Wiggins’s £6000 Hour Record chain (video)

Muc-Off has released details of the preparation of the chain used by Bradley Wiggins to break the Hour Record.

Sonic cleaning of chains after testing

Breaking the Hour Record calls for attention to every detail and this included the chain used on Bradley Wiggins’s bike, with lubricant manufacturer Muc-Off claiming that the total cost amounted to £6000.

>>> The tech behind Wiggins' Hour Record

Muc-Off has developed a machine to quantify the efficiency and durability of its chain lubricant formulations. Called the CLOD (which stands for Chain Lubricant Optimisation Dynamometer), this machine measures the friction generated in running the chain. There’s a video of the machine in use below.

http://www.youtube.com/watch?v=XCGyR9KgxLs

Muc-Off tested over 30 Shimano Dura-Ace chains to select the most efficient, before deep cleaning them in a sonic bath. Muc-Off’s team then applied a specially formulated lubricant treatment with military grade high pressure additives to reduce friction.

>>> Muc-Off's Team Sky lubricant

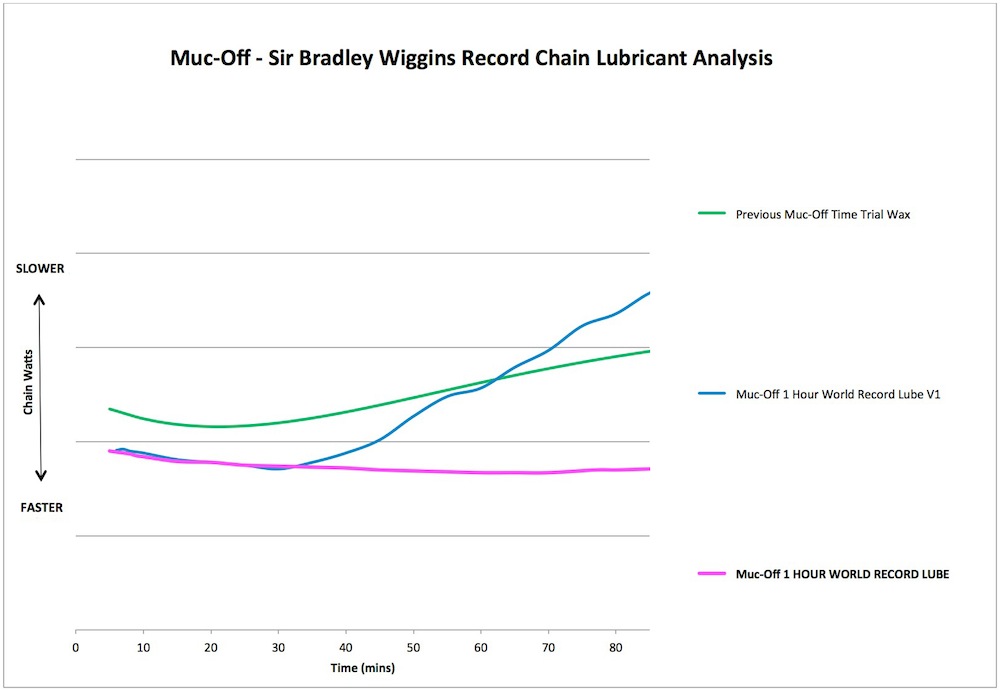

Muc-Off proved that the new formulation showed limited performance degradation over an hour of running and has published a graph showing its performance over the hour relative to its other formulations. This shows that friction losses in the chain started off as low as other formulations and remained low throughout an hour of use, whereas other tested formulations generated increased friction losses over the course of an hour.

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

The chainring which Wiggins used was also run in by Muc-Off in advance of the record attempt, to ensure that it was optimally prepared.

Bradley Wiggins's time trial minute man

Paul started writing for Cycling Weekly in 2015, covering cycling tech, new bikes and product testing. Since then, he’s reviewed hundreds of bikes and thousands of other pieces of cycling equipment for the magazine and the Cycling Weekly website.

He’s been cycling for a lot longer than that though and his travels by bike have taken him all around Europe and to California. He’s been riding gravel since before gravel bikes existed too, riding a cyclocross bike through the Chilterns and along the South Downs.