New Continental GP5000 S TR is hookless compatible but the brand wants you to follow the rules

Continental is encouraging education over recommended tyre pressure, if you are going to run a hookless tyre and rim - so we decided to show readers what happens if you don't

Up until now, the Continental GP5000 has been the go-to example used in the arguments against hookless rims: “not all tyres are compatible, the GP5000 being a notable exclusion,” is a sentence cycling journalists have had saved in the copy/paste bank for a while now.

Whether due to desire, or due to pressure from wheel brands, Continental has now resolved that: the new Grand Prix 5000 S TR is compatible with hookless rims. It is also reportedly faster and lighter due to a move from a three-ply construction, to two.

Continental says that the Grand Prix 5000 S TR has been in development since 2018, and it’s been raced throughout the 2021 season. It was the tyre Fillipo Ganna used en route to World Championships time trial glory.

However, the brand is keen to emphasise that the maximum tyre pressures, and other guidelines, must be adhered to - and we put that to the test to explosive effect.

Continental Grand Prix 5000 S TR: what’s the significance of going hookless?

Hookless rims have been around for aeons in the automotive and mountain biking industries. These rims are - as the name suggests - free of hooks. They make it easier to mount a tubeless tyre, they’re cheaper to produce, and it’s “easier to make a hookless rim lighter”, as Continental’s Jan-Niklas Jünger put it.

Some road brands - including, until today, Continental - have not approved their tyres for use with hookless rims, citing safety concerns.

Without a hook to secure the tyre, it could blow off the rim if the pressure is too high. The ETRTO guideline sits at 72PSI.

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

One of the key benefits of a tubeless set-up is the ability to ride a lower pressure without fear of pinching a tube; whilst Continental says higher pressures are faster on the butter smooth roads, in reality, most roads are littered with imperfections, where low pressure wins the race due to the tyre deforming over bumps. Therefore, exceeding 72PSI on a tubeless set-up isn't desirable, but, that doesn't mean no one will do it.

Cycling Weekly understands that some wheel brands have tested wheel/tyre combos up to and beyond 120 PSI, without them blowing off the rim. When they have blown off the rim, this has usually been following the failure of the bead, as indicated by snapping which would make the tyre no longer usable. We've included images from this testing below.

This was in a controlled lab environment, with the goal to far exceed safety standards before determining if they wanted to adopt hookless rims. Anything over the industry or brand recommendations would be considered very dangerous to try at home (please, don’t).

Keen to see how the new Continental tyre would fair when put under extreme pressure, I fitted the Grand Prix 5000 S TR - in its 28mm guise - to a Zipp 353 NSW (with 25mm internal width), and pumped to 100 PSI. I turned my back, and no more than 10 minutes later the tyre blew off the rim with a very loud bang.

I repeated this test, with both tyres - to the same effect.

A 28mm tyre on a 25mm internal rim width is flying quite close to the sun. So, I tried the same test on a 303S, which has an internal rim measurement of 23mm. The tyre blew off the rim, again, though it took a few minutes longer to happen.

In each case, the bead showed no obvious signs of total failure, the tyre could still be fitted and re-inflated. An industry expert confirmed that this suggests the tyre has stretched, causing the blow off, as opposed to a complete failure. This is something, he said, he'd expect to happen as a result of a bead that has been made very supple, to aid ease of fitment.

I have cut the tyre, to show you the bead, so sadly I won't be able to bring ride impressions on these.

The Zipp wheels were selected purely because they were readily available, the rim tape was applied by Zipp, in the channel only and not protruding on to the edge (where tape could increase the chance of a blow off). I've ridden these rims with Zipp's tyres, as well as Schwalbe tyres.

Asked if there was anything in Continental's construction of the GP 5000 that might make it more susceptible to blowing off the rim, the reply was: "We test and confirm to be used with a max pressure and still have a safety range. More than max. pressure should not be used or tested, being it to experiment or to mount the tire."

With wheel/tyre standards and recommendations having changed so dramatically in the last few years, we wholly advise that users pay very close attention to the guidelines.

As does Continental.

“No, I’m not surprised [the tyre blew off the rim at 100PSI]”, Jünger says.

“The industry guidelines say that a tyre must [not blow off the rim] at 110 per cent of the maximum pressure, without sealant or silicone spray; internally, we test to 130 per cent, with sealant and silicone spray,” he tells me. My test at 100 PSI represents 136 per cent of the maximum pressure, and therefore Continental passes its internal test as well as the industry standard.

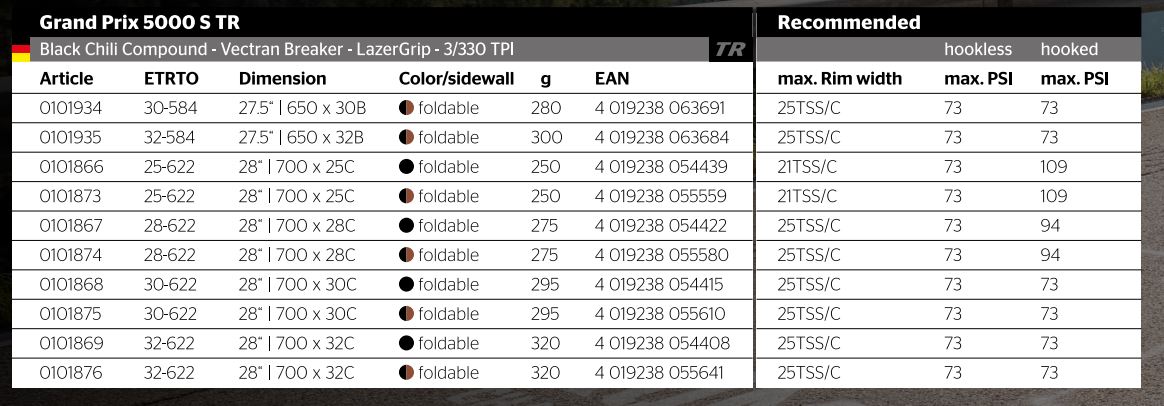

Jünger was keen that, at Cycling Weekly, we make it abundantly clear to readers that they must follow the guidelines laid out by the brand - and asked us to publish these.

Asked about the benefits of hookless rims, Jünger - who studied textiles engineering - said he thought they made perfect sense for gravel and mountain bike riding.

For road riders, he told us "they have less scrub [wastage] in production, it is easier for them to be lighter, production costs less."

That's great for manufacturers. For users, he added: "claims that hookless is faster, more aero, or stable, by our testing, we are not able to confirm that."

With more and more wheel brands adopting hookless technology, however, it’s possible Continental simply couldn’t afford to be left behind.

Fitting the Continental Grand Prix 5000 S TR

Whilst my willful attempt to blow the tyre off the rim was successful, running it as intended was much more pleasant. At 73 PSI, the tyre stayed comfortably on the rim.

On the first attempt, I was almost able to fit the tyre without the use of a tyre lever, just using a tool to pop the final 2cm of bead into place. This became easier on the second fitting. The third fitting required no tyre lever. The process took less than five minutes - something that could not be said of Continental’s previous GP 5000 TLR tyre. I didn't need a booster pump, either, a track pump alone was sufficient.

Continental Grand Prix 5000 S TR: what else is new?

According to Continental, the new Grand Prix 5000 S TR is 20 per cent faster, 50 grams lighter and has 28 per cent more sidewall versus the outgoing tyre. Most of that is because it now uses a two-ply construction, as opposed to three-ply.

The new tyre uses Continental’s BlackChili Compound, which is said to provide the “ultimate balance of rolling resistance, grip and longevity” whilst the Vectran Breaker is all about puncture and tear resistance.

The GP 5000 S TL replaces the GP 5000 TLR, but Jünger did point out that consumers are more than welcome to run it with a hooked rim, or "if you're riding one time trial [on smooth surfaces, where Continental still says higher pressures are faster], just put a tube in it."

Continental Grand Prix 5000 S TR specifications

- Black sidewall tires

- Weight - 250g / 280g / 300g / 320g

- Dimensions - 25-622 / 28-622 / 30-622 / 32-622

- Technology – Black Chili compound, Vectran Breaker, LazerGrip

- Transparent sidewall tires

- Weight - 250g / 280g / 300g / 320g / 280g / 300g

- Dimensions - 25-622 / 28-622 / 30-622 / 32-622 / 30-584 / 32-584

- Technology – Black Chili compound, Vectran Breaker, LazerGrip

- Pricing and availability

- Available to purchase from 4th October worldwide, RRP 79,90€ per tyre

Michelle Arthurs-Brennan the Editor of Cycling Weekly website. An NCTJ qualified traditional journalist by trade, Michelle began her career working for local newspapers. She's worked within the cycling industry since 2012, and joined the Cycling Weekly team in 2017, having previously been Editor at Total Women's Cycling. Prior to welcoming her first daughter in 2022, Michelle raced on the road, track, and in time trials, and still rides as much as she can - albeit a fair proportion indoors, for now.

Michelle is on maternity leave from April 2025 until spring 2026.