What are hookless rims and do you need them?

With the big wheel brands launching new rims with straight sidewalls, we ask whether hookless technology can benefit your bike riding

Zipp 303 S hookless

Before the 1970s, the only choice for racing was a tubular rim, whereby a tubular tyre would be glued on. For all other types of cycling the only option was ‘wire-on’ tyres, which had a rigid wire bead and were heavy and slow.

The arrival of Mavic’s Module E rim in the mid 1970s changed all that. It incorporated a hook shape to capture a lighter, foldable bead and prevent it from blowing off under high pressure. And it’s taken from the 1970s until now for road cycling to get more or less in line with all the other modes of pneumatic tyred transport – including mountain bikes – and use hookless rims with tubeless tyres.

They’re hardly universal yet, but several brands responsible for producing some of the best road bike wheels, including Roval, Enve, Zipp, Corima and and Giant/Cadex, are all getting behind the 'new' hookless tech. But are they really better than the traditional hooked type? More importantly - are they safe? And should you be riding them?

“There are a number of misconceptions about hookless rims,” says Bastien Donzé, Zipp wheel product manager. “First is that hooks on the rim are necessary to ensure safe retention of the tyre. Our testing shows that tyre burst pressure or tyre blow-off is very similar on hookless rims to hooked rims.”

Zipp recently launched a new 303 S and 303 Firecrest, both of which use hookless rims, but the maximum recommended pressure is just 72psi – and at the moment Zipp has a list of only five brands that have confirmed their tyres are compatible with Zipp’s hookless rim. “It's not because 72psi is the limit of the wheel but that's because that's what's imposed by regulations like ISO and ETRTO [European Tyre and Rim Technical Organisation],” Donzé explains.

Moreover, with hookless rims designed for 28c tyres, a higher pressure is not only unnecessary but detrimental to the wheel’s performance: “Even on smooth asphalt roads you’re saving 3-5 watts on bigger tyres and lower pressure. On rougher surfaces, your savings are up to 40 watts.”

>>> Are wider tyres really better?

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

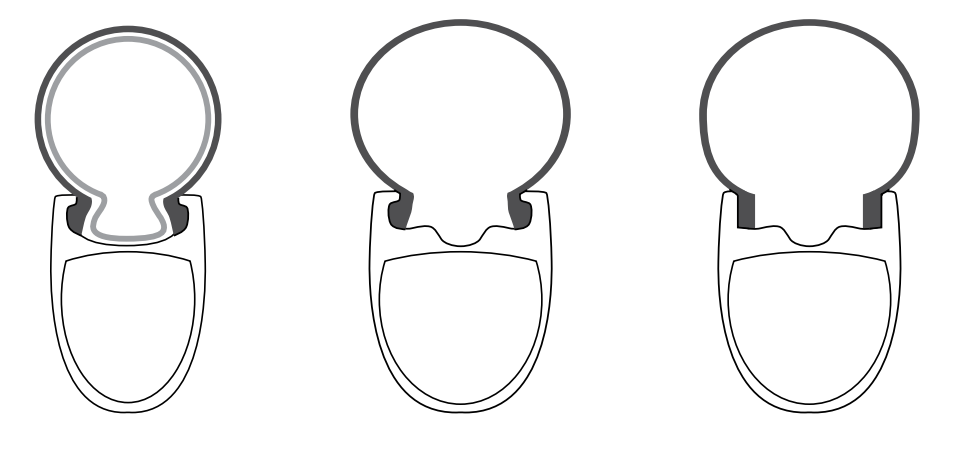

The key to the better performance is that the sidewalls are spaced further apart in a hookless rim and supported better since the bead is not pulled inwards by the hook. “A big tyre on a traditional rim will be like a lightbulb in profile. With hookless the tyre sidewalls are being supported a lot better. You get the full the benefits of a big tyre and low pressure without any of the squirm or the rolling resistance.”

Hookless also reportedly has an aerodynamic benefit, as Donzé explains: “Because the tyre is not pinched, you have a much cleaner transition between the rim and the tyre. Even though the rim is wider and increases frontal area, the system with the tyre is quite a bit faster.”

Hookless rims are made using a simpler but superior manufacturing process, says Donzé, which results in better compaction of the carbon, better resin distribution through the rim, tighter tolerances in the tyre bead seat, less waste and less scrap.

“For carbon rims with a hook you have to design a soft mandrel made of silicone that can squeeze into the hooks and mould the tyre bed cavity. Using a soft mandrel you're losing manufacturing accuracy and generally you end up putting in more material. When you go to hookless you can replace that silicone mandrel with a steel one that gives better accuracy [so a better interface with the tyre] thanks to better compaction of the resin that also results in more strength on the wings of the rim. The silicone mandrel is one time usage – it has to be thrown away after every use, so that’s a lot of waste. The steel one lasts thousands of cycles. There's a reduction of the costs, which equals a lower price for the end-user, as demonstrated by the new price of our 303 wheels."

And finally, thanks to the better resin distribution achieved by the hard steel tool, a hookless rim saves a considerable amount of weight over a traditional hooked rim with no strength penalty: “We were able to save 300g with the 303 Firecrest,” says Donzé, “and it’s just as strong in terms of impact.”

While Zipp is committed to educating the cycling community about the benefits of running bigger tyres at lower pressures, Giant has accepted that not every road rider is willing or able to run 28c tyres at 72psi. "The key thing for us is being able to run the regular pressure of the tyre, up to and including the maximum pressure that's printed on the sidewall, so that the rim is no longer a limiting factor," says David Ward, Giant product and training manager.

Ward also argues that not every road rider wants 28c tyres: "We’re making rims in 19 and 21mm widths and we’re making wheels and tyres so you can run hookless down to a 23c tyre and up to 125psi. Of course nobody should actually be running their tyres at 125psi but we need to build in that possibility of someone running it at maximum pressure, hitting a pothole, and having a dodgy gauge on a track pump. It’s a safety issue so we do have to take it very seriously."

Like Zipp, Giant has published a list of compatible tyres that are safe to inflate beyond the ETRTO maximum pressure of 72psi if they've passed Giant's testing protocol, which involves inflating them 1.5 times the tyre's maximum recommended pressure on a Giant hookless rim.

"Rather than relying on the tyre brands saying yes it is or no it’s not tubeless, hookless compatible, we’re working with all the tyre brands to our protocol," says Ward. "If a tyre is on our approved list it’s approved by us and the tyre brand. For example the Schwalbe Pro One – Schwalbe are 100 per cent happy to say yes, their tyres will work with our rims.

However, as with Zipp, the Continental GP500 TL and Vittoria Corsa are not on Giant's approved list.

"Conti have been very open to working with us and Vittoria the same and they want to change. All the tyre brands are seeing the benefits of hookless and seeing that hookless is going to get bigger and bigger, especially with Zipp getting behind it. If we could say the GP5000 TL and the Corsa and Corsa Speed were hookless compatible it would take down everybody’s defences. And I’m pretty confident that in two-to-three years’ time every new tubeless tyre will be hookless compatible as standard."

Not everyone is convinced as to the benefits of going hookless, though, with safety still a factor under debate.

Dov Tate, founder of British wheel brand Parcours, weighs up whether the key driver for hookless rim development is improved performance or cheaper manufacturing costs: "Manufacturing hookless is cheaper, that's not up for discussion," he says. "If you've got a hook you're talking about multi-dimensional moulding technology. Hookless is just a straight steel mandrel. I'm undecided on it.

"There is an argument that it makes for a slightly better rim/tyre interface in that you have a slightly smoother interface. Because the hook, if it's not well designed, will be putting inward pressure on the tyre making it slightly more lightbulb shaped.

"But the big issue hookless has at the minute is with pressure ratings," says Tate. "With big off-road tyres you're never going to be at the sort of pressure where you're running the risk of blowing off. But on the road, all the pressure recommendations on new hookless road wheels are really low", 72psi is the [ETRTO] recommended limit for a hookless tyre.

Tate continues: “Also some tyres, such as the Continental GP5000, aren’t compatible with hookless because the bead on the tyre isn't quite guaranteed to hold the seal.

“If you get the right tyre and rim you’re fine,” says Tate. “The problem is that because hookless technology and even tubeless tech doesn't have clearly defined standards, there are too many variables to be able to guarantee that every tubeless tyre will be able to fit on every tubeless rim above 72psi and that's why ETRTO haven't signed off on it yet.”

Tate says Parcours didn’t want to restrict tyre choice when it developed its latest wheel, the Strade, and argues that other brands have had to compromise in that area in order to have a hookless rim. “Whether they're doing that for performance or cost reasons, I don't know for sure,” he concludes.

Our view

It does seem high time that road cycling’s rim and tyre technology caught up with that of motor vehicles and mountain bikes, and hookless does offer undisputed benefits, but the current uncertainty over tyre compatibility could be off-putting for some. Other more traditional road cyclists could find the low maximum pressure off-putting despite tests demonstrating that with 28c tyres and bigger, lower pressure means faster rolling.

No: Dov Tate, Parcours

“It’s a fact that manufacturing hookless is cheaper. And there is an argument that it makes for a slightly better rim/tyre interface because that interface is slightly smoother. But tyre choice is restricted and maximum recommended pressure is low.”

Yes: Bastien Donzé, Zipp:

“The drawbacks at this point are really about tyre compatibility, but this is being addressed in the regulatory committees (ETRTO and ISO), and will soon become a non-issue. In summary, hookless rims are lighter, faster, stronger, more affordable and better for the environment. The end-user wins at every level, really."

Simon Smythe is a hugely experienced cycling tech writer, who has been writing for Cycling Weekly since 2003. Until recently he was our senior tech writer. In his cycling career Simon has mostly focused on time trialling with a national medal, a few open wins and his club's 30-mile record in his palmares. These days he spends most of his time testing road bikes, or on a tandem doing the school run with his younger son.