Santini turn to manufacturing face masks amid coronavirus crisis

The brand said it can make 10,000 a day if the design is approved

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

You are now subscribed

Your newsletter sign-up was successful

Italian clothing brand Santini has begun creating face masks at its factory just outside Bergamo, in response to the coronavirus pandemic.

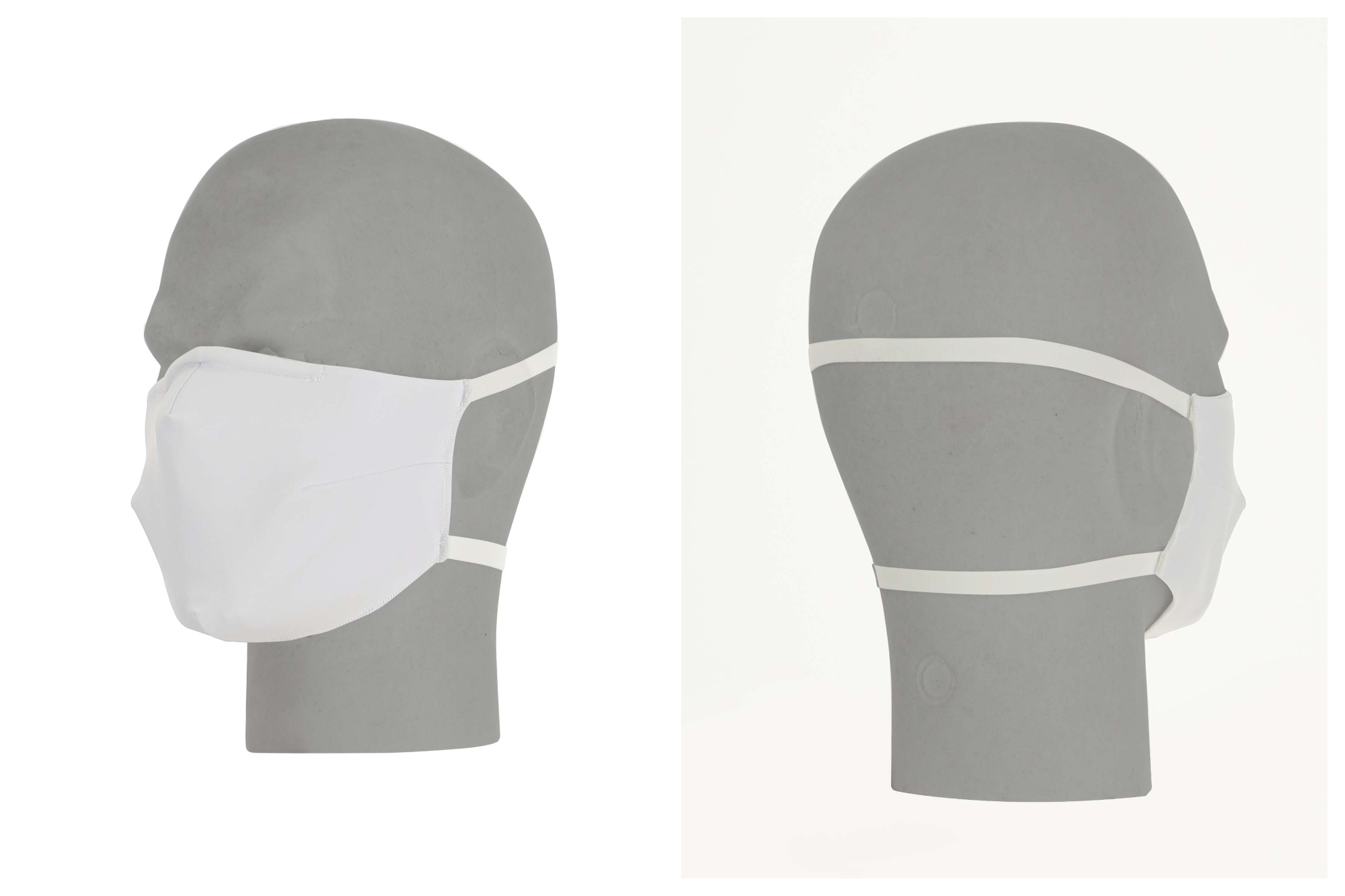

The brand is making double layer face masks using Monica Acquazero fabric. The fabric is traditionally used as part of Santini's triathlon suits and comes from Sitip - a textile manufacturer from the Bergamo area.

Currently, the face mask is a prototype - Santini is awaiting certification from the Politecnico di Milano. However, if approved, the brand says it can begin production and that it would be possible to make 10,000 a day.

The Monica Acquazero fabric by Sitip is a 220g material, with anti-water and anti-splash treatment. The mask construction is 78 per cent Polyester, 22 per cent Lycra and comes with a metal nose pad with a double elastic securing it around the back of the head.

The mask can be re-used up to 10 times after washing, can be washed at 90 degrees and is sanitisable. It can be dried in the dryer.

Commenting on the decision to begin making the masks, Santini's Marketing Manager Paola Santini said: "Since the beginning of this emergency, we have wondered how we could do our part. We know that in hospitals, but also in companies, there is a strong need for face masks to reduce the spread of contagion from Covid 19 coronavirus. We therefore thought, together with Sitip, to create our face mask prototype with waterproof and anti-splash treatment, the Monica Acquazero fabric."

She added: "The strongest motivation is to be able to help and support our country. The priority will be addressed to Bergamo and its province, because we know the difficulty of our hospitals and of the people who work in factories."

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

It took the company around six hours to develop the prototype, though Santini adds that they continue to work on improvements.

The Santini factory is continuing to operate, in compliance with all the restrictions and rules applied according to government laws, and the brand told Cycling Weekly that whilst staff welfare was paramount, it was not expecting a shortfall in its standard product as a result of the virus. However, moving to production of the masks will have an effect.

"It has already [had an effect on production of our normal product]" Santini said "even if we haven’t started [mask] production yet. We set up a team that is working on the reorganisation of our production floor to make face masks and on new improvements to make. We know that time is key so we started with sending our first mask to test while we are already working on new improvements."

Michelle Arthurs-Brennan the Editor of Cycling Weekly website. An NCTJ qualified traditional journalist by trade, Michelle began her career working for local newspapers. She's worked within the cycling industry since 2012, and joined the Cycling Weekly team in 2017, having previously been Editor at Total Women's Cycling. Prior to welcoming her first daughter in 2022, Michelle raced on the road, track, and in time trials, and still rides as much as she can - albeit a fair proportion indoors, for now.

Michelle is on maternity leave from April 2025 until spring 2026.