How sailing technology could lead to a new wave of aero design

Parcours wheels' founder and Huub Wattbike's sports scientist used marine wind sensors to establish what they say is the "next frontier" of aero testing – and are about to publish their research

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

You are now subscribed

Your newsletter sign-up was successful

Measuring wind angles using ultrasonic sensors placed at different points on a bike and using the data to design wheels, frames and components is the next step in aerodynamic bike design according to Dov Tate, the founder of British wheel brand Parcours.

There are three main tools used for testing aerodynamic performance: Computational Fluid Dynamics (CFD), velodrome testing and wind tunnel testing. In these controlled environments, accuracy is high, but they’re not representative of real-world cycling conditions, in which the yaw angle is constantly changing as wind and rider direction vary. So mapping data from wind tunnel to real world has long been understood to be challenging – but until now, no one has come up with a way to measure the changing wind conditions of outside riding in enough detail that they can improve aerodynamics in a meaningful way.

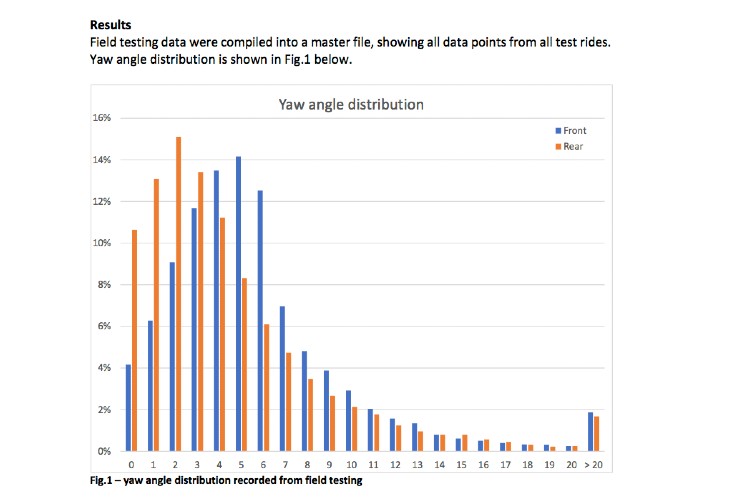

Tate, who is an Oxford engineering graduate, worked with Dr Steve Faulkner at the sports engineering department at Nottingham Trent University – who has also worked with the Huub Wattbike team – to conduct an analysis of real-world conditions leading to the development of the Parcours Strade wheelset, launched in 2020, which features different front and rear rim profiles. Using marine anemometers (which measure wind speed and direction) located at the front and rear axles, the team found the average yaw angle at the front wheel was consistently higher than at the rear: airflow at the rear was affected by the front of the bike and rider’s legs, feet and pedals.

The Strade’s resulting blunt, wide front rim and deeper, V-shaped rear tested very fast against the competition, setting a new benchmark for a mid-depth disc wheelset, according to Tate.

Now Faulkner is preparing to publish an independent peer-reviewed paper on the research, which he and Tate say could revolutionise the way cycling products are designed and selected for specific conditions and for specific competitions.

“What we know from applied aerodynamics – and in my work with Huub Wattbike I also learned a lot there – is that what you measure in a wind tunnel or on a velodrome doesn’t always translate,” said Faulkner.

Tate continued: “At the moment the entire cycling industry is working around that singular dataset to map from wind tunnel testing to real world performance. But what we’re saying is you should be thinking more about the location on the bike, and that you’ve got a differential airflow.”

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

Tate explained that engineers are constantly trying to work out how to optimise their product design for the right yaw angle, which he defines as the sum of a crosswind element and the headwind you’re creating from your forward velocity.

“In a wind tunnel the testing is all done at fixed angles. They’ll run a range of angles to create the different wind conditions. Then, if you want to look at how that translates to the real world, you effectively need to know what the average yaw angle is that a cyclist outside will experience.

"So you could do it very simply and say ‘the average yaw angle when you’re riding outside is 4.5 degrees’. But because of the nature of an average there will be times when the yaw angle is zero and times when it’s 10. Some lesser times when it’s 15 or 20. So the more advanced approach is to go out and collect some data or real-world yaw conditions so you can apply a weighted average. You could then say you spend 15 per cent of your time at between four and five degrees, then one per cent between 18 and 20, so you would weight the different data points from the wind tunnel differently. And that’s how we go from a wind tunnel chart which shows the drag at all different yaw angles, to one fixed figure. When you say that a bike or wheelset is 15 watts faster than a competitor or previous model, you’re doing that based on a weighted average yaw angle. Or you should be.”

Tate explained that collecting the data for a weighted average has previously been challenging, with a few different ways of doing it. A very basic way that some brands have used is to get Met Office data for wind, sum that with an average ride speed and then figure out what yaw angles you’ll be seeing. This is what he calls “a purely desktop exercise.”

The problem with that purely desktop method, he continued, is that Met Office weather stations are supposed to be 10 metres above the ground. And the wind conditions at an altitude of 10 metres are very different from those close to the ground, because of what’s called a boundary layer effect. Friction between the airflow and the ground means that the wind is substantially slower closer to the tarmac.

“A more accurate way of collecting yaw angle data is to put instruments on a bike. This has been done by a few different brands and researchers. You can have a weather vane on a stick out the front of the bike. Which is much more accurate because it’s at the height at which the air is hitting the bike, but in order to get accurate data from it they put it quite a way out in front of the bike. So what they’re saying is that’s the clean air that you’re hitting, and that’s quite applicable to the leading edge of the bike, the front wheel, the rider’s hands or front of the body.

"But what got me thinking was two things: first that that’s still a fairly crude way of collecting the data. It’s an analogue sensor, there’s friction in the apparatus and it’s not going to respond very quickly and there will be some element of smoothing to it. Secondly, it might be accurate for the front of the bike but it doesn’t take into account the impact of the bike and rider on the airflow as you go further back."

Those thoughts led Tate to discuss the problem with Dr Steve Faulkner, and the sports engineering team at Nottingham Trent University.

Ultrasonic accuracy

“There’s a new range of instruments that were developed for the sailing world, ultrasonic wind sensors," Tate went on to say. "They are much smaller, the size of a fist. Around the rim they have four ultrasonic beams that beam sound waves through a little gap. Those sound waves are disturbed by airflow. As a result it can figure out the speed of the airflow and the direction. So it gives you the apparent wind – from that you can get the yaw angle and the wind speed. The really nice thing about these sensors is that you can place them at different points on the bike. This is where it got really interesting.

"By the time the airflow reaches the back of the bike your body, the frame and equipment will already have had an interfering effect on it. So logically you’ve got a sum of two forces: the airflow that’s hitting the back of the bike clean – so coming in from the side – and then you’ve got the dirty airflow from the front that has already hit the side of the wheel and is coming straight back along the bike. So if you sum those two vectors, the yaw angle for the back of the bike should theoretically be lower. So the project really was to test that hypothesis.”

Tate and Faulkner validated all their real world data – "back-solving" – by putting the sensors on a bike in the wind tunnel.

Tate said this informed the design philosophy for Parcours’ ongoing product development, with the Strade the first wheel to be developed using it, and another one in the pipeline. “Everything we do will have this dataset behind it and it’s the cornerstone of what we’re doing aerodynamically.”

Tate said he and Faulkner want to publish their findings not only because they want to be transparent about the data but also because they want to show that they’re at the cutting edge in terms of the research process. But isn’t there a danger of other wheel brands with bigger budgets using the data and overtaking Parcours?

"If you look at the design of Enve wheels, actually the new Roval wheels do [use similar differential front/rear profiles]. I don’t know whether that’s the driving force behind it because they’ve not publicly stated it. I’m sure Zipp or Roval or Mavic could take this data and use it in their own design work, but I feel at the moment the best they could do is match us. We’ve got a year and a half’s head start. I would also be very impressed if they could deliver a comparable model at a comparable price given their business model," Tate said.

"So it is a risk, but I think it matches my approach to the brand, which has always been openness around data. I don’t want to say ‘just trust us on this’. I'm going that step further and looking for the peer review for the publication to become the almost generally accepted dataset, which I think it should be.”

Wider implications for product design

Although Tate said that as a wheel brand he has focused on placing sensors at the axles for his data, beyond wheel design the use of small sensors clearly has much wider implications: “If you’re designing a frame, should all of your foil shapes be identical whether on the front fork or rear chainstay? Probably not. If you’re going to be putting a sail water bottle behind the saddle, do you need to think about the airflow there? If you’re an aero helmet designer, particularly with the proliferation of the arms-up positions, should you be looking at the airflow both at the front of the head and the rear, for the tail design? Should you be just applying this one dataset, which has almost been taken as gospel by the cycling industry until now, or should you be thinking about where the actual item is?

“What we’re saying is you should be thinking about it differently and we’ve got the data to show it. That’s from a pure design perspective, but actually you can take it further and say, because we’ve got this smaller sensor that you can chuck into an envelope and ship anywhere in the world, you bolt it onto your bike and carry a couple of phones in your pocket and you’ve got your dataset, could you be thinking about collecting more data to say these are the conditions in the UK, but for a coastal and windy place, the conditions would be very different. If you’re in the Tour should you be thinking about different equipment for a coastal stage, one of the early sprint stages or the Mistral stages versus a mountain stage where you’re covered by trees?”

As well as wheel choice, Tate sees tyre aerodynamics becoming more significant: anecdotally, he found the Vittoria Corsa Speed to be fast at lower yaw angles, but with a small lip between the cotton sidewall and the rubber tread it stalled earlier at higher yaw angles and therefore, he said, might not be the optimum choice in strong crosswinds.

“In a way it’s only the first step,” said Tate. “We’ve answered our own question: does the wind condition vary at different points of the bike? Yes. We’ve got a dataset that’s particularly relevant for wheel design, because that’s where our focus is, and it’s informing the design philosophy across pretty much everything we’re doing now. And the follow-on question is, how else can this be applied in the cycling world? People are always thinking about whether we’ve reached peak aero. But is this one of the next frontiers. Rather than thinking about peak aero for the whole system, let’s break it down and look at smaller components. We’re not necessarily going to be getting 10 or 20 watt savings like before, but at risk of going back into that marginal gains philosophy, a watt here at watt there and you probably could deliver something of that order. So it asks more questions than it answers, but it’s an interesting first step.”

Faulkner concluded: "We’ve taken technology that comes from sailing and that’s enabled us to take these measurements and no one’s done that before. So it’s really a case of developing a methodology that really is innovative, a model, and that’s where the clever thing lies. It’s not ‘we’ve got a power meter and a weather vane.’ We’ve gone out and found something that will give us the information we need. You hear about the shark suit that Speedo developed – they’ve looked at nature and thought OK, a shark is the fastest thing in water, let’s mimic that. We’ve looked at other sports where an understanding of the weather and the wind is important. Ah, sailing, they must have something. And incorporated that into our data collection."

Steve Faulkner is a cancer survivor and is this year riding the full Tour de France route one day ahead of the pros with former England footballer and leukaemia survivor Geoff Thomas – who he is also coaching – in a team of 25 riders raising £1m for Cure Leukaemia. He has a JustGiving page and all the details are on the Cure Leukaemia website.

Cure Leukaemia is the Tour’s first official charity.

Simon Smythe is a hugely experienced cycling tech writer, who has been writing for Cycling Weekly since 2003. Until recently he was our senior tech writer. In his cycling career Simon has mostly focused on time trialling with a national medal, a few open wins and his club's 30-mile record in his palmares. These days he spends most of his time testing road bikes, or on a tandem doing the school run with his younger son.