Making Tracks: building the Olympic velodrome

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

You are now subscribed

Your newsletter sign-up was successful

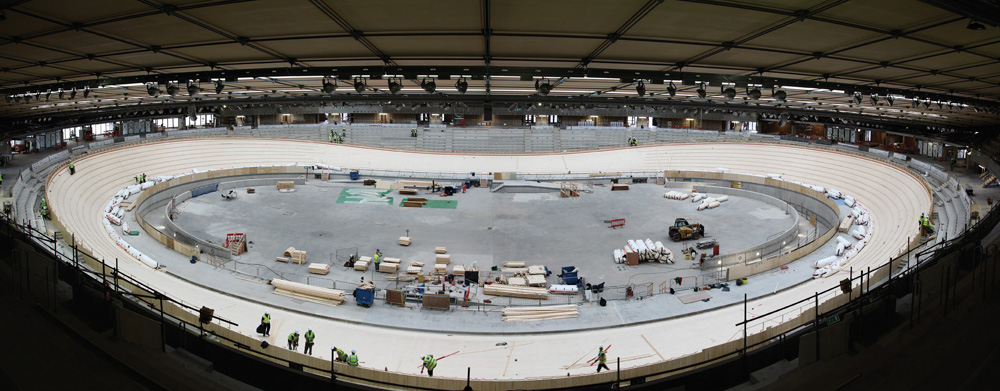

Cycling Weekly visited the London velodrome in September 2010 while it was being built to interview track designer Ron Webb. This is the feature that appeared in the November 25th, 2010 issue of Cycling Weekly.

After completing construction of the Newport track in 2003, Ron Webb thought he had finished with building cycling tracks.

With Olympic tracks in Athens, Sydney and Seoul, Commonwealth Games tracks in Edinburgh, Manchester and Melbourne and the installation and construction of countless other tracks under his belt, the Australian's work appeared done.

Then he was approached by the Olympic Delivery Authority to build the track at the London velodrome for the 2012 Games. "They approached me two years ago," he explained. "I live in Staines - not far down the road - so it was a nice thing for me to come and do."

Both physically and conceptually, the track is central to any velodrome. To design the track then build around it "is the only way to do it," Webb asserts.

And indeed when we entered the London velodrome to take a look at the project ourselves, it was the wooden surface of the 250-metre track that immediately grabbed our attention.

Maybe it was the lack of clutter in the track centre. Or that racing lines had yet to be painted on the boards. But from where I stood in the track centre, it looked wider and more circular than most other tracks I'd visited.

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

"The straights are not short but the bends are nice and long," confirmed Webb. "I like that because the most important part of a bike track for a racing cyclist is the exit from the curve into the straight."

Perfect Banking

Webb admits he has obsessed over the exit from the banking ever since he was a professional racer himself. Behind the big motors at 90kph, he really got the feel for the difference between a good and bad exit.

"The whole secret of a bike track is really that exit from the curve and the way it joins on to the straight," he said. "The wider the curve, the nicer it is. If someone is trying to pass on the curve, then they can ride shoulder to shoulder.

"This is very similar to the Sydney Olympic track and Melbourne and Newport," continued Webb. "The only difference is: every time I build a track I'm always tweaking that exit. If you have a racing yacht you're always fiddling around with the keel. With me I'm always fiddling around with the angles coming out the banking."

Given Webb's attention to detail and London's expectation to host the best games ever, the ODA has been hyping London's new velodrome to be the fastest in the world. Webb, however, is not so keen to toe the party line.

"Everyone does that," he said "It's hubris isn't it? We all hope there will be more records here than in Beijing. But what I'm doing is building a stage for the actors. And it's the actors who make the records."

Theatre of dreams

Although, as Webb says, it is ultimately the people on the boards who define the quality of the action, the atmosphere of the whole theatre will also have an effect. Although Webb expresses reservations about some of the ideas, he believes the cavernous feeling of the new 6,000-seat stadium that surrounds his track should help.

"I think Newport is a super track but Newport would probably never bring a world record and a lot of that is to do with the building," he explained. "Being a tin shed, it's very claustrophobic. When you're going round the bend and leaning over, you don't get that big feeling of freedom which you do in Manchester or [will do] here."

As well as its size, there are other features built into the Olympic stadium to help achieve high speeds. Two of these came at the recommendation of Sir Chris Hoy. The first is that the temperature shouldn't drop whenever a door is opened - thus all entrances to the track are double-doored. And while this conforms to Team GB's perspective of warmer is faster, Webb isn't so impressed.

"I don't like it too warm because it affects the track a lot," he says. "Timber will move - you'll never stop timber moving - but you get shrinkage of the timber if it's hot."

Because of this, Webb has made an arrangement with the ODA that there will be no high heating on as the track beds in over the next few months.

Hoy's other recommendation concerns a ring of seats all the way around the track to prevent the ‘wall of silence' riders can experience on the banking where there are typically few spectators. Although, like on most tracks, the multiple rows of seats along the straights taper away into the falling roof and rising trackside on the curves, there will be at least three rows of seats all the way around.

Behind these rows at the ends of the track you can see large windows that form a ribbon all the way around the stadium. When the velodrome is completed and the protective coating comes off, these will combine with the long strips of skylight to let in plenty of natural light.

Although seats had yet to be attached when we visited, an abundance of wood panelling - and the Olympic ban on on-track advertising - mean the finished product will look exquisite.

From the outside, the velodrome is shaping up to look equally classy. When we stepped out, men in half a dozen cherry pickers were fixing sustainably sourced western red cedar cladding to the outer walls. On top, the Pringle-shaped roof defines the velodrome's sleek, space-age form.

And with the bowl of the velodrome buried four metres into the landscaped earth, the aforementioned ring of glass sits at ground level to create an illusion that the velodrome is hovering. Unlike most velodromes we've visited, this one is a stunning piece of architecture.

There is, however, a flipside to the iconic roof. Supposedly designed to reflect the geometry of the cycle track, from the inside, it conversely struck me of being at odds with the track's dynamic. Where the track rises for the banking, the ceiling at the ends sinks towards it. As the track drops into the straights, it curls up high into the gods.

From the top seats - while not obscuring a view of the track itself - the ceiling interferes with your line of vision. That makes me feel slightly uneasy. And while I realise this is very much a pernickety personal view, it perhaps also relates to Webb's comments on claustrophobia.

For a rider high on the banking, will that dipping roof also seem too close? Then again, with the seating configuration, perhaps the crowd will raise it.

On the level

Back down at track level, I was walked around the boards by chief track builder PJ Lane, who has worked alongside Webb since building the Meadowbank track in Edinburgh. Along with twenty five colleagues from Irish firm Cornerstone Construction, he had been assigned to London for the nine-week track build.

"It's definitely the best track I've ever worked on," he enthused before explaining how it all took shape.

The track rests on 356 trusses, each one varying in angle. On top of that lies the racing surface: strips of 40mm-wide prime Siberian pine.

Lane explained that most of these are of between 5.1 and 6.1 metres in length, pre-machined and washed, with knots that are as small as possible. By the time the track had been completed last week, the workers had gone over every centimetre of it, sanding edges and filling gapped joins.

The quality of the timber is a highly important matter. Webb explained that the builders had been forced into rejecting the first batch after the agency appointed with handling supplies for the Olympic Park had initially ordered from an inferior source.

"I've been buying this timber we've got now from the same source since the 1970s," Webb explained. "It grows right up in the north of Russia in the permafrost of the Arctic Circle. It grows very high and very straight to give good long lengths. And if you look at the end of the timber, the growth grains are very tight together. It's almost like a hardwood in growth. But it's very manageable and very, very strong."

Easy Upkeep

After the track is built, Webb doesn't anticipate being involved in its maintenance but believes it should last for 30 or 40 years. "The surface got changed in Manchester a few years ago and I never thought it was necessary," he said. "All that was wrong was it was dirty. If you looked at cut-offs of the timber that came off, it never even went in half a millimetre.

"Dirt and dust are the enemy of any velodrome," he continued. "When doors or skylights are opened there will always be dust coming in. And dust sits on the track and the tyres grind it in."

Webb pointed out that in this respect, the construction of the track had been compromised: "In an ideal world, we wouldn't be here now but six months later when the stadium is finished. Now there's a lot of dust in the air that settles on the surface. Even though they'll brush it, dust on the surface is like ball bearings under the tyres."

The ODA announced completion of the timber parts of the track last Thursday, with the racing surface due to be covered with a plastic membrane. It will thus be ‘mothballed' while being allowed to breathe. Not until the rest of the stadium is completed and the track UCI inspected, will the boards actually be ridden on for the first time.

The Velodrome in Numbers

250m – the track's length

56,000 – the cumulative length of the timbers used

356 – the number of trusses beneath the track

6,000 – the number of seats in the arena

200 – the approximate number of stray cats that had to be accounted for before construction could be finished

130m – the length of the roof

120m – the width of the roof

10,000 – the workforce during peak period contruction at the Olympic site

12% – the minimum gradient on the straights

43% – the maximum gradient on the bends

300,000 – the number of nails used in the track's construction

Related Links

Olympic Velodrome opens tomorrowRon Webb: the big interview