RLS takes the fight to Mips for the helmet safety crown but is RLS the next household name in helmet safety?

RLS has taken a known problem and come up with a new solution to it, but is it better than the incumbent, Mips? We went to the factory to find out.

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

You are now subscribed

Your newsletter sign-up was successful

I’m in a high-tech factory space in Bow, East London, meeting with Jamie Cook, inventor of a new helmet tech ingredient, Release Layer System or RLS. Our conversation starts in a room surrounded by broken or half-made helmets and as much as the tech I’ve already seen here is cool, it’s also pretty grim.

The solutions we’re discussing today are about preventing life-changing brain injuries in helmeted sports contexts, and the at first trivial-looking litter surrounding me, from some of the 5000 plus individual helmet tests they've undertaken here, is sobering. As I sit down and reach for the cuppa they’ve just made for me, we start discussing just how many friends we know who have been impacted by head injury whilst riding a bicycle.

We take turns around the table, exchanging our own emotional examples, until we get to Nick from Fusion, the PR company that set up the meeting. By now, the tone is pretty sombre. He doesn’t add his own example as such, but nods, as if in recognition that he too knows someone who’s suffered the same tragedies, which Cook and everyone who works at RLS insists could be preventable.

Cook kicks off his presentation with an alarming statistic: 2.8million people participate in helmeted sports, and receive blows to the head which meet a ‘Level 2’ classification, which is the way the medical and scientific community refer to a knock on the head that can create a concussive injury, or TBI. TBI stands for Traumatic Brain Injury and how they have been mitigated to date, is by an approach to helmet design which, essentially, comes back to the forces required to crack someone’s skull open.

The expanded polystyrene (EPS) helmet liners we’re all familiar with in cycling, motorsport, snow sports – almost anything that requires the wearing of a helmet – are, if you look at a range of helmet manufacturers, largely the same. In concert with the outer shells, and various other items contained in a typical helmet, those polystyrene designs are fundamentally there to reduce the impact of a crash on your skull.

That was until Mips arrived on the scene. Mips is Swedish invention, and now a well known helmet ingredient brand, which provides a lightweight technology that helmet brands can licence and install inside the EPS liner of a helmet.

In a crash, the Mips system creates a ‘release’ layer inside the helmet that reduces the rotational forces the helmet may otherwise transfer to the head. And it’s popular. Mips has become a near household name among those who wear helmets for work or leisure, thanks to the significant impact their technology has had on the market in recent years. Its presence in the best cycling helmets is now something we always look for when reviewing these products.

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

In lay terms, the demand for these systems is about reducing how much your soft and jelly-like brain is twisted around when you whack your head.

The twisting creates shearing forces inside the brain, tearing it from the inside out. Systems like Mips, aim to reduce the impact on the brain by ensuring that, rather than the helmet staying in a fixed position, the internal liner slides and allows the helmet to rotate about the skull, transferring less rotational force into the brain.

Cook, owner and founder of RLS, explains:

“Helmets used to be tested by dropping them onto a very flat surface. You’re basically trying to measure the compression of the foam in these tests, to understand how much energy that helmet could absorb to prevent a skull fracture.”

He then cups his hands as if holding something in both of them, with open fingers.

“If I held your brain in my hands, it would actually somewhat seep through my fingers. It’s very soft, almost jelly-like. When you rotate something soft, it can actually begin shearing inside and that shearing can rupture and detach the neurons and axons within your brain tissue. That can lead to TBI – which can be anything from concussion, to a bleed on the brain. Where helmets are great at absorbing blunt forces, in an angled impact, they can actually act as a lever arm, and increase the torsion on the brain.”

Then, Cook places a snowglobe-like item in my hand so I can experience the concept of my brain cells ringing around for myself. I’m encouraged to hit the side of the snowglobe. When you do, I see that the flakes move suddenly, but remain relatively collected at the bottom of the globe.

When you grip it with your fingertips from below however, and gently twist it back and forth, as if mimicking a kind of Royal wave, the particles spin upwards violently, in a twister-like motion which fills the liquid in the snow globe almost instantaneously. It’s pretty compelling.

I’ve seen enough of these kinds of demos before, and over the years, you develop a healthy cynicism for them, but this simple device helps paint a pretty strong picture that this problem definitely isn’t imagined.

Cook then plays a video that demonstrates the amount of turning force present in a typical glancing impact. I can see clearly how the EPS liner and shell of the helmet initially absorbs the impact. However, as the helmeted 'head' in the test video passes beyond the initial point of impact, a rotational force acting on the head and neck becomes apparent. It looks uncomfortable to watch, and clearly devastating if you’re the dummy in the helmet.

The next video is the same shot taken from the same angle, in the same test – this time with RLS tech fitted to the helmet. Not only is it clear, side by side, that the helmet can now slide, as the ball bearings act to release and roll the panel in contact with the impact site, the reduction in rotational force moving through the helmet, into the skull and even neck is not just clear, it’s extraordinary. They also have the data to back this up, for anyone thinking they’d put Kool-aid in my cup of tea.

Moreover, the numbers they shared indicate that not only can the RLS technology enhance some of the best cycling helmets on the market, but it can also bring a relatively ordinary performing helmet up to the high standards required to pass the most stringent tests, such as the Virginia Tech standards.

I continued to ask probing questions based on what they were showing me, insofar as a non-expert can, and every question is answered cooly, collectively, and often with data from yet another slide to support their answer.

As my cynicism subsides into genuine intrigue, I’m keen to see the tests myself, so we head into the test lab next door.

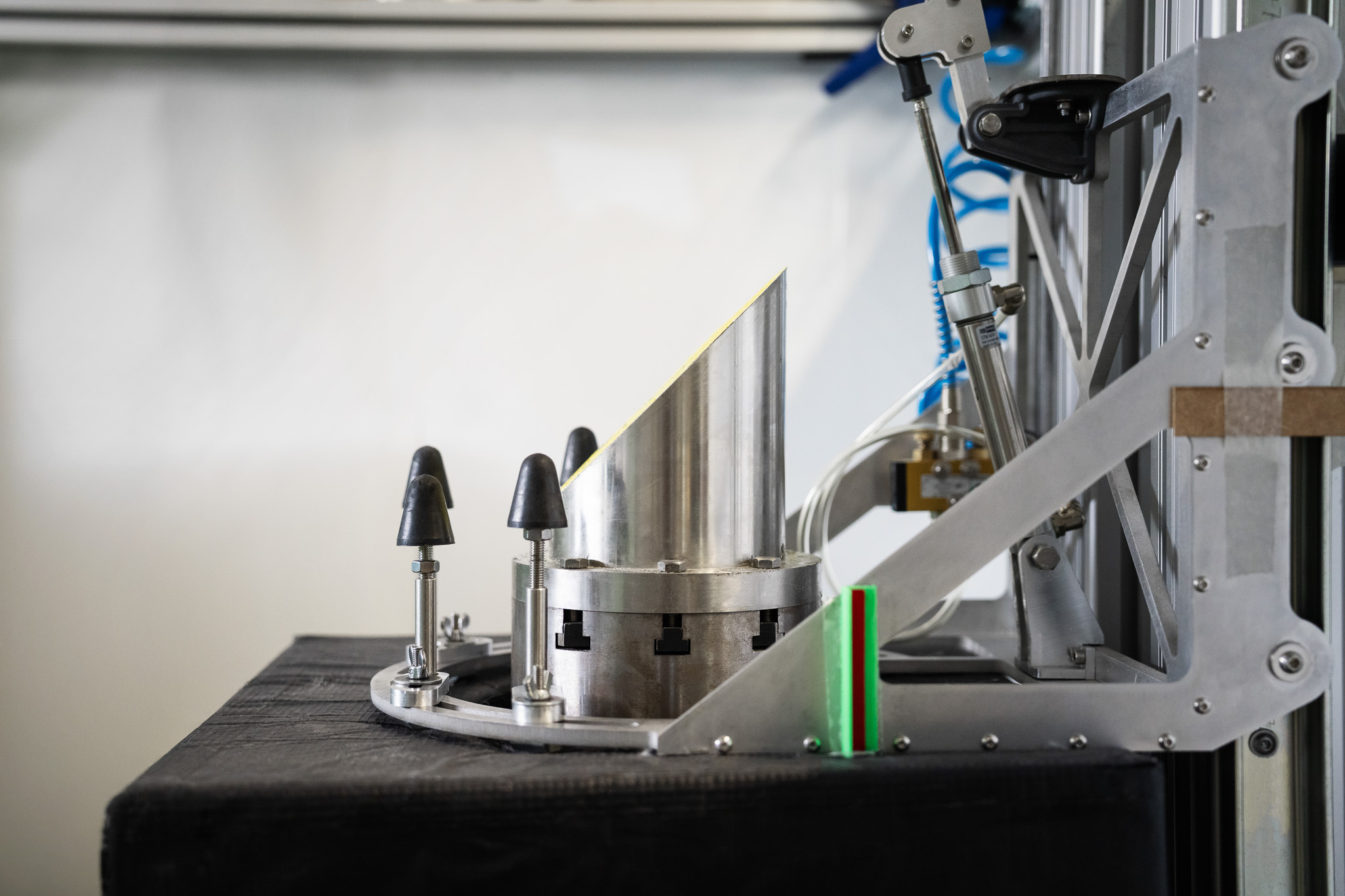

Two lab technicians are overseeing the operation of an enormous test rig, and they welcome me in before setting up a test. They ask Cook which standard I’d like to see a test done to. I gestured towards the screens which outlined all of the available standards – they have protocols for all of them, in all key markets, including the new and more stringent Euro (EU) legislation which they inform me is on the way. Cook instructs them to go for the hardest current one, the Virginia Tech rated test.

In this test, I witnessed a helmet being elevated to what must have been far beyond the mezzanine area of this industrial unit. It was very high.

The engineer then shouts, primed, or something similarly official, and follows with the word, “dropping”. The helmet with its dummy head fitted into it drops to earth in a blink, striking the angled metal impact zone with enough violence to make me shout “f*ck” out loud and involuntarily. I looked around to see everyone looking at me, in full expectation that that was going to be my precise reaction.

The shell of the helmet is then handed to me, and I’m surprised to see that this relatively basic helmet was still in one piece. I had to look for the damage pretty carefully, but it was there, and eventually very clear. Multiple cracks throughout the structure of the EPS liner. It had absorbed a hell of an impact and remained intact. It was nothing short of remarkable. That’s not a scientific measure of course, but the severity of the impact in the test concerned was surprising and this humble helmet had clearly done it’s job to an extent you wouldn’t necessarily think was possible without seeing it for yourself.

The next test was on the same model of helmet with the RLS system fitted. No heavier with the system in place, or not so you’d notice, otherwise, the helmet was the same, except for panels of what I now knew concealed hundreds of tiny bearings, positioned with over the backing tape for the RLS system. The shell element was affixed to it using a relatively common 3M-manufactured mechanical fastening tape, which has hooks to help it mate to the other side. This works a little like a more precise version of Velcro, or a sticklebrick, perhaps more relevantly, which locks onto itself but can break in a heavy impact, a similar impact to those most likely in a Level 2 concussive event.

The second test was no less violent, although I did manage to stop myself from swearing. What was very clear is that the helmet was nowhere near as damaged, and in the final moments of the impact, you could witness the crash test dummy form inside it, continuing, almost entirely without the rotations visible in the first impact, just as I had seen in the video.

The set-up at RLS, as I’ve seen and been told, currently has the capacity to manufacture 250,000 RLS units per year. I watched every aspect of the production process, and while precise and undoubtedly very hard to design initially, it looks remarkably effortless using the high-tech and immaculately presented machines I saw in operation. Dare I say it, the solution seems simple in terms of how you’d imagine a manufacturer taking it on. The panels themselves are cut to size precisely to match the design of the helmet, around vents and all, and constructed and shipped to the client helmet brand’s destination factory. Once there, you need a relatively well-trained but low-skilled factory operative to affix it to the final helmet as part of the standard assembly process.

With Canyon already on board, and the compelling evidence I’ve seen with my own eyes I think it is a case of, if, not when, you’ll see this being added to your favourite helmet brands products, and potentially replacing Mips altogether.

It’s not especially heavy, or troublesome to adapt to fit on almost any helmet. That didn’t seem to be a barrier, although it is an obvious question. It also seems to be pretty novel and effective, and the company has lodged some 25 individual patents well ahead of production, with more to come. It seems relatively sure that the RLS system is more than protected in terms of IP, and to me, it genuinely feels like it could be the next big household name in head protection, and much sooner than you might think.

Still, I think we might need to grab some popcorn, whilst we sit back and watch the incumbent and RLS duke it out for the crown, as regardless of the clear homework that's been done here to clear the way for this new player, I'm sure they're still going to argue over who came up with what, first.

If I know one thing to be true, you don’t always have to be first to market with an innovative way of solving a problem, you just have to do it better than the last lot. And in that sense, if the tests I've seen are to be believed, RLS really could be onto something.

Andy Carr is the tech editor at Cycling Weekly. He was founder of Spoon Customs, where for ten years, him and his team designed and built some of the world's most coveted custom bikes. The company also created Gun Control Custom Paint. Together the brands championed the highest standards in fit, fabrication and finishing.

Nowadays, Andy is based in Norfolk, where he loves riding almost anything with two-wheels. He was an alpine ride guide for a time, and gets back to the Southern Alps as often as possible.

You must confirm your public display name before commenting

Please logout and then login again, you will then be prompted to enter your display name.