Enve launches 'more accessibly priced' Foundation Collection wheels

New price-point wheels will still be handmade in Utah

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

You are now subscribed

Your newsletter sign-up was successful

Enve, the performance wheel brand which makes all of its rims in-house in Ogden, Utah, has launched a new collection aimed at providing its highly regarded products at a lower price point.

The wheel manufacturer is fiercely proud of its innovations and reputation, but its hand built products have historically come at a price - with models often costing upwards of £3k and thus effectively out of reach for the majority of riders.

To combat this problem, Enve has unveiled its 'Foundation Collection', with three new wheelsets; two for road riders and one mountain bike set, each retailing at £1800.

>>> Read: ENVE SES 5.6 Disc wheelset review

Each model in the Foundation Collection has been designed to achieve best-in-class performance and will still be handbuilt at Enve's facility in Ogden, Utah.

What makes this even more impressive is the wheels also give owners access to Enve’s pro-level Lifetime Incident Protection scheme - if you break your Foundation Collection wheel, Enve will replace it, no matter how the damage has occurred.

The first two road series wheels are purpose built, aero road wheels developed to meet the demands of the modern road cyclist – the Enve 45 and 65. Named after their respective rim depths the name also pays tribute to the original Enve road wheels that were introduced to the aftermarket in 2007.

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

Foundation Collection Need to Know

To achieve a low drag and high stability performance in the Enve 45 and 65 rim shape, Enve has taken cues from its SES rim shape development with the major difference between Foundation and SES being that the Foundation rim geometries are matched front to back.

As a result of this development, Enve says the 45 and 65 hoops deliver drag reductions similar to, or better than, the competition’s wheels that are well upmarket in price.

The Enve 45 and 65 are most efficient when paired with a 25mm (labelled) tubeless road tyre. For riders wishing to run larger 28mm tyres, aerodynamic losses are minimised by the efficiency of the rim’s shape, and losses are readily recovered by the rolling efficiencies gained from the higher volume tyre.

The Enve 45 and 65 feature a 21mm internal rim width and a hookless bead profile and are designed to be run primarily as tubeless. Enve has provided a list of available tyres that have been tested and approved for use with the new wheels. For a tyre to be approved and recommended for use, it must pass a maximum inflation test where the tyre is inflated to 1.5x the max pressure of the rim or tyre, whichever is lowest.

Additionally, Enve has a tyre pressure chart to aid customers in achieving their optimal tire pressures.

The Enve 45 and 65 also feature Enve’s patent pending Wide Hookless Bead technology. This technology is defined as a wide surface at each of the rim’s leading edges. By creating a larger surface area at the rim’s leading edge, impacts from curbs, potholes, and debris are distributed over a larger area, reducing the likelihood of pinch-flatting tubed and tubeless tyres alike. Additionally, this feature increases the rim’s impact toughness.

Enve has utilised its patented process of molding spoke and valve stem holes - this results in rims that are stronger and lighter. Because carbon fiber gets its strength from continuous fibers, Enve routes the fibers around the hole without cutting them which increases the strength of each spoke hole. This technique pays large dividends in the final product by creating a lighter and stronger rim.

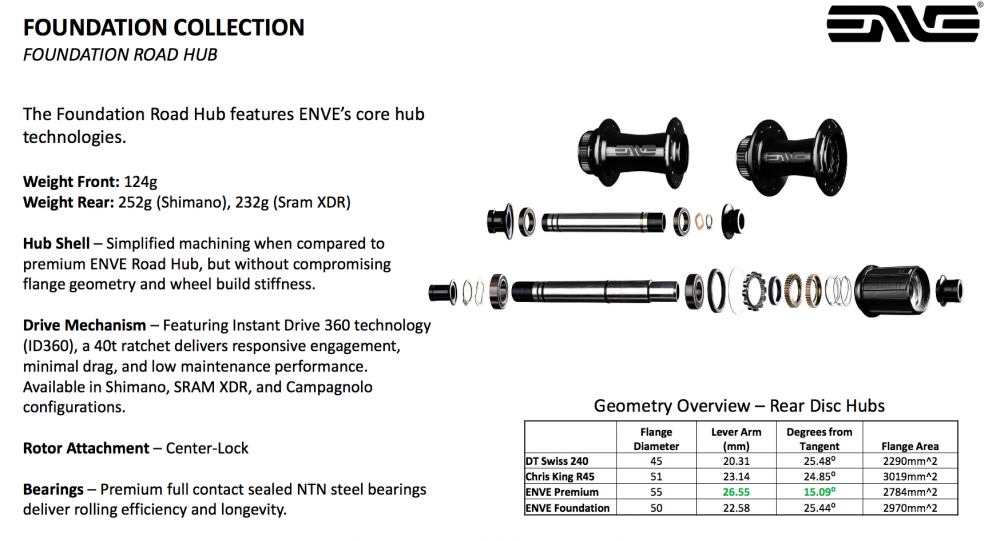

These hoops offer up Enve's own Foundation Road Hub which utilizes the same internals as Enve's premium hub offering, but with a simplified hub-shell. Like their premium hub offering, the Foundation Road Hub utilizes the tried and proven ID360 40t ratchet drive mechanism and Enve’s maintenance free automatic preload system aptly referred to as Perfect Preload. This system eliminates the possibility that the hub will develop bearing play and slop over time. It also eliminates the need for the consumer to adjust preload on their own as ride time is accumulated.

The Foundation Road Hub features premium grade, fully sealed NTN steel bearings.

The Foundation Collection’s Enve 45 and 65 model road wheel models are available to purchase immediately, and are exclusive in the UK to Sigma Sports.

James Bracey's career has seen him move from geography teacher, to MBR writer, to Cycling Weekly's senior tech writer and video presenter. He possesses an in-depth knowledge of bicycle mechanics, as well as bike fit and coaching qualifications. Bracey enjoys all manner of cycling, from road to gravel and mountain biking.