Pinarello creates 'impossible' 3D-printed alloy bike to help Filippo Ganna break the Hour Record

Ineos rider hopes to break the current record later this month on a bike inspired by nature

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

You are now subscribed

Your newsletter sign-up was successful

What do humpback whales, Dan Bigham and 3D printing machines have in common?

The answer is they’ve all played a part in the design and development of Filippo Ganna’s new track bike for his upcoming UCI Hour Record attempt this month.

Pinarello appears to have left few stones unturned in its pursuit of creating the fastest bike possible for his ride against the clock on October 8 in the Grenchen velodrome in Switzerland.

The Italian brand, which provides the bikes for Ganna’s Ineos Grenadiers team, has taken both familiar and unfamiliar routes to what it hopes will be the fastest pursuit bike ever built, the Bolide F HR 3D.

The obvious headline grabber is the manufacturing process used to create Ganna’s new Bolide. 3D printing, Pinarello says, allowed for the introduction of “new shapes and features that are impossible to replicate with existing carbon-fibre techniques”. The result is the first - and Pinarello hopes the fastest - high performance 3D printed bike ever built.

Aerodynamic performance, power transmission and comfort, all designed around Ganna’s “unique anatomy”, were the primary goals. All were made possible, Pinarello believes, in no small part by the powers of 3D printing, which allowed for added internal reinforcement and new tube shapes.

Crucially, it also “drastically cut development time”, with Pinarello no longer “held back” by the time constraints of a traditional, and far slower, carbon-fibre mould process.

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

Teaming up with the UK-based Metron AE, led by Dimitris Katsanis who designed the iconic UKSI track bike, the Bolide HR was designed around Scalmalloy, a high-strength scandium-aluminum-magnesium alloy that’s been specifically created for a 3D printing application and is already being used to manufacture commercially available components like the 3D-printed Mythos Elix stem.

The new frame comprises five parts - the front triangle is made up of three parts, with the seat and chainstays two more. They are then bonded together using an aerospace-grade epoxy. The aforementioned reinforcement comes in the form of titanium used on both the fork head and the handlebar extensions - two high stress areas of the bike.

To measure the bike’s strength a copy of the frame was sent to Germany for independent testing. The Bolide passed with flying colours, becoming the first fully-rideable UCI-compliant aero bike to pass the ISO4210.

The HR, in an unbranded prototype form, has already proved successful in the real world, helping Ineos performance engineer Dan Bigham to a new Hour Record in August. Bigham helped develop the Bolide F HR 3D frameset as well as other components to be used on Ganna's machine, including the crankset.

So what are some of the key developments that Pinarello hopes will assist Ganna in breaking one of cycling’s most storied records?

An analysis of drag distribution showed that the seat tube and the seat post combined contribute almost 40% of the frame and fork’s total drag. Air flow around this area is especially turbulent given that the rider's legs are constantly deflecting the air surrounding them, and in an alternating fashion. Rather than stay attached to the seat tube, the airflow is constantly separated from it, creating an area of low-pressure and as a result, drag.

To combat this Pinarello turned to nature. Humpback whales to be precise.

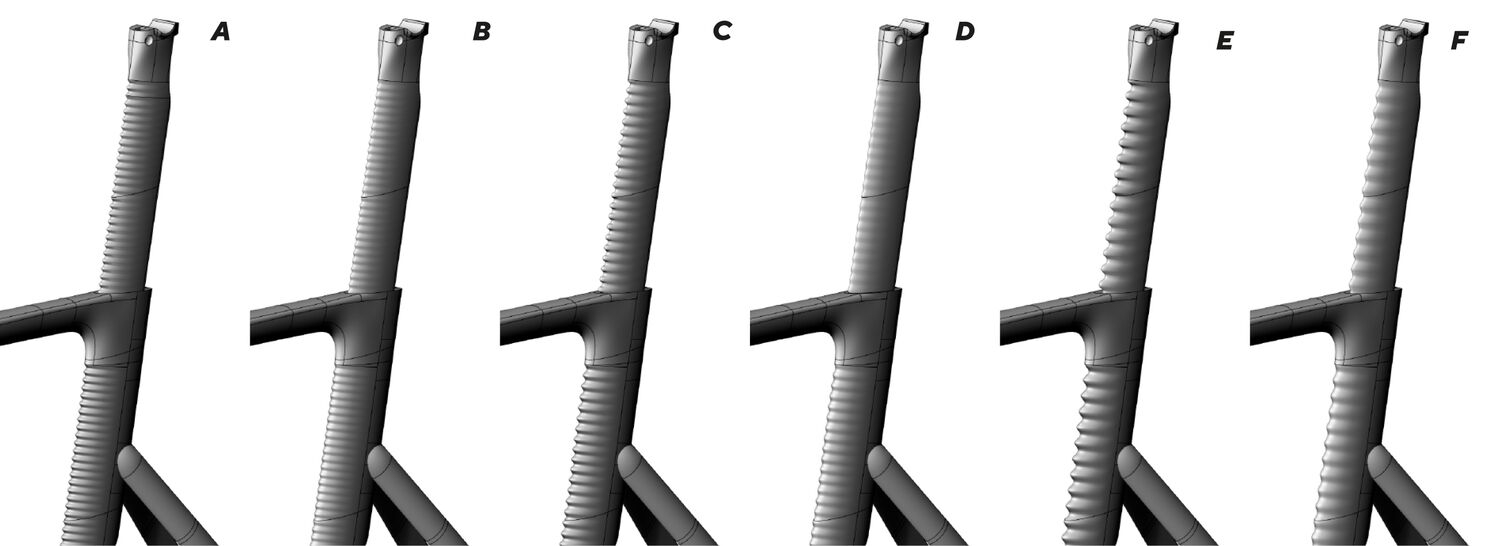

Extensive studies by the University of Adelaide have shown that the whale’s ability to manoeuvre in the ocean, including tight turns belying its large size, are aided by protrusions on its front flippers. The researchers took their data to both aircraft and bicycles, even filing a patent for frame design in 2016. An integral part of their research showed that by mimicking the protrusions on a bike’s seat tube, in the form of ridges, the separation of airflow could be minimised, in turn reducing the drag.

Pinarello took this research and applied it to the new Bolide. Alongside R&D partner NablaFlow, it ran numerous simulations on AeroCloud, to find the most effective design pattern. After further CFD and wind tunnel testing using live riders, AirStream technology was born. AirStream uses what Pinarello calls “a unique pattern of AirNodes on the frame that takes full advantage of the University of Adelaide's pioneering research”.

The Bolide frame design also takes advantage of the removal of the UCI’s 3:1 rule, which stated that "the ratio between the length and the width of equipment cannot exceed 3:1." Airfoil tube sections became deeper and slimmer, with ratios of 6:1 and as much of 8:1. This is particularly noticeable in the head tube, down tube and seat tube of the Bolide.

Pinarello has also narrowed the bottom bracket from 70mm to 54mm and the wheel hubs from 120mm to 89mm on the rear, and from 100m to 69mm on the front, helping to reduce the bike’s frontal area. Tradition has been maintained in the Bolide’s fork and seat stays however, using what Pinarello calls the “proven method” of using narrow fork and stays, which sit closely to the bike’s disc wheels.

The Italian marque helped pioneer metal 3D printing in cycling back in 2015, when it supplied the handlebars for Bradley Wiggins’ successful hour attempt. Once again the bars were an area of focus, with Pinarello designing a set with the aim of reducing the drag of bike and rider combined, rather than just focusing on the bike, a common ‘mistake’ of many earlier attempts to produce a more aerodynamically efficient machine

While the unusual shape of the handlebars create a ‘drag penalty’, they also reduce Ganna’s drag by a greater amount. The 3D printed bars, created through several rounds of CFD optimisation, also underwent rigorous testing by Metron to ensure their shape didn’t create any structural issues.

Remarkably, the Pinarello Bolide F HR 3D will be available to the masses, with ordering via Pinarello’s official retailers and then built on demand.

For more information visit pinarello.com

Luke Friend has worked as a writer, editor and copywriter for over twenty five years. Across books, magazines and websites, he's covered a broad range of topics for a range of clients including Major League Baseball, Golf Digest, the National Trust and the NHS. He has an MA in Professional Writing from Falmouth University and is a qualified bicycle mechanic. He has been a cycling enthusiast from an early age, partly due to watching the Tour de France on TV. He's a keen follower of bike racing to this day as well as a regular road and gravel rider.