Titanium for the masses: Why titanium bikes are riding high and how companies are bringing the cost down on this boutique material

Canyon, Blackheart, Priority, Decathlon are all dabbling in titanium – here’s why

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

You are now subscribed

Your newsletter sign-up was successful

Titanium alloy has long been considered the ideal material for long-lasting and smooth-riding bicycles. It has a high strength to weight ratio, is extremely corrosion resistant and can be turned into bikes that have, some say, special riding characteristics.

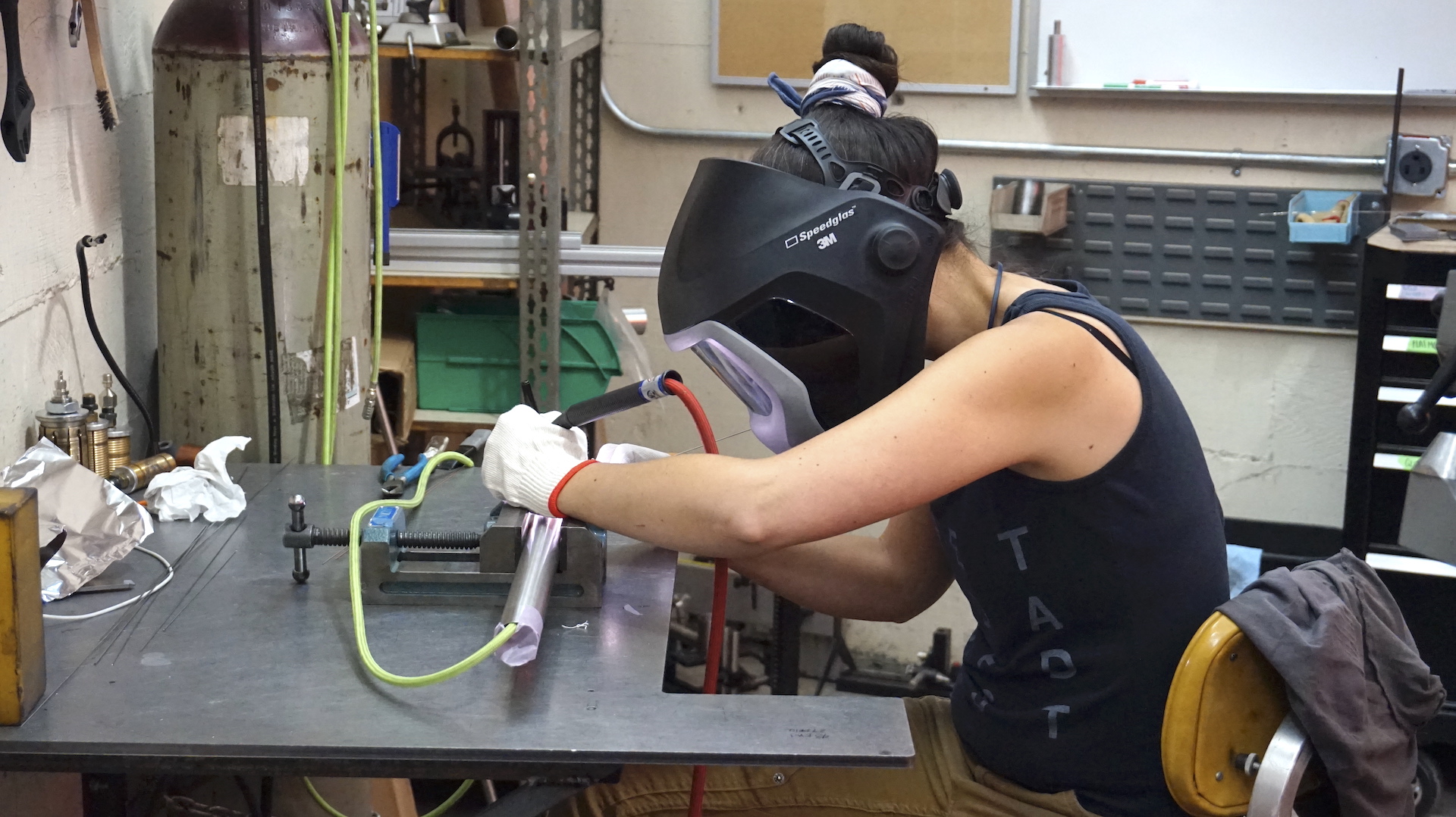

The drawback of titanium, however, is that it is expensive: both the price of the raw material and the specialized techniques required to turn it into bicycles are costly. For example, a titanium frame needs to be welded with shielding gas to avoid exposing the weld to oxygen and compromising its integrity, which makes the process more complex than TIG welded steel or aluminum.

Carbon fiber has been the predominant material for racing bicycles for decades now, due to properties that allow it to be unbelievably light yet strong and also aerodynamically optimized. But, like any frame material, it has inherent tradeoffs, in this case, reduced durability.

Despite carbon’s near-stranglehold on high-end bicycles, metal bikes still make up a robust slice of the overall pie, and more are coming.

Every material has its own characteristics, which good design can emphasize, and poor design can inhibit. Ultimately the material itself is less important to how the bike functions than the design and fabrication techniques utilized.

Despite carbon’s near-stranglehold on high-end bicycles, metal bikes still make up a robust slice of the overall pie and more, affordable, titanium bikes are coming. Why Cycles, Priority, Ribble and Triban (Decathlon) are all making affordable titanium bike frames. Even Canyon is rumored to come out with a ti bike. We set out to investigate why that is, understand how this expensive material can be made more affordable, and see how these bikes compare against higher end options.

Not all ti is created equal

First things first: It’s important to note that there are different grades of titanium, and not all titanium bikes are made of the same stuff, though they do all share excellent corrosion resistance. At room temperature, titanium alloy reacts with oxygen to form a protective titanium oxide layer, which means that titanium doesn’t rust, and thus performs well in harsh conditions with little upkeep. It also doesn’t require paint to maintain its integrity.

Titanium bicycles are typically made out of two different types of tubing: drawn and welded. Drawn tubes are manufactured by extruding raw materials into seamless tubes, whereas welded tubes are made out of sheets of titanium that are then bent and welded together, which is a less expensive manufacturing technique.

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

But why this interest in titanium

As for why titanium is a popular material to utilize at the moment, it’s closely tied to the current boom of gravel riding. As more and more people venture off-road to explore unpaved routes, they’re realizing that their needs are different. Lower speeds mean aerodynamics are less critical, so round tubes don’t pose a problem. Rough and tumble trails and long days in the saddle make durability and impact resistance important, which are two areas where titanium excels. And technical terrain means frame compliance (comfort) is more desirable than pure stiffness and power transfer.

Another reason why titanium is currently in vogue, which we heard from several sources, is because it is perceived as more timeless than carbon, and thus suitable for riders seeking a so-called “forever bike.” Whether the material itself actually lends itself to this is debatable, but this is the widely held perception.

For a brand built around ‘low maintenance,’ titanium offers clear advantages. The material is more durable over time with great responsiveness and vibration dampening.

Priority Bicycles

We found many common threads between the various different companies we reached out to. Across the board, titanium was selected for its low maintenance, durability and unique ride characteristics.

Priority Bicycles, which specializes in commuter and recreational bicycles, said that, “for a brand built around ‘low maintenance,’ titanium offers clear advantages. The material is more durable over time with great responsiveness and vibration dampening. We want our riders to be able to have bicycles that are easy to ride, own, and maintain.”

Priority offers its Apollo Gravel complete bike featuring an internally geared belt-driven drivetrain and a titanium frame for $3,999.

French company Decathlon, which makes bicycles for leisure and endurance riders under the brand Triban espouses a similar sentiment: “Decathlon has a history of building steel and titanium bikes, and we wanted to design a gravel bike with lots of comfort, first and foremost, but also high performance. Carbon gravel bikes are more associated with performance, and the team wanted to create something different—a bike where the only limit of where it can go is the rider.”

This bike, the Triban Gravel 900 Ti is designed for comfort, with adventure riders in mind. Retail price is $3,999. The company also produces a line of carbon racing bicycles under the Van Rysel brand, which is a new sponsor of the Decathlon AG2R La Mondiale World Tour team.

BlackHeart Bike Company is a newer brand out of California that offers titanium gravel bikes. It produces nine different sizes of its Allroad Ti frameset, which retails for $2,999, and like the others, titanium was chosen for both its durability and simplicity. I spoke with Zach Lambert, the company’s founder, who described how he was unable to find the bike he wanted—an elegant titanium bike that wasn’t too specialized in any one way—so he decided to start his own brand. The company now offers several models and also sells aluminum frames and complete bikes.

Cost, explained

A $4,000 bicycle isn’t exactly affordable, but given the nature of the material, it represents a reasonably good value. Many boutique titanium brands don’t even offer framesets for that amount. A full built bicycle from say Moots, No22 or Firefly starts at five figures.

So how are these brands able to keep the cost down?

A direct-to-consumer sales model is one way, and BlackHeart utilizes this model, as do Priority, Decathlon and Lynskey.

Priority said this model works because it cuts out costs associated with in-person sales, and “by selling direct, with in-house customer service, and fast turnaround on orders, we are able to keep our prices very competitive. We also don’t offer in-house customization.”

In addition to selling direct, these companies have been able to find other efficiencies. For example, Decathlon mentioned that its business, which is vast, “can provide our products at an exceptional value with our vertically integrated business model, which keeps our product design, manufacturing, and sales in-house.”

The labor required to build a quality titanium bike is significant, and the tier-1 welders that make these bikes are few and far between.

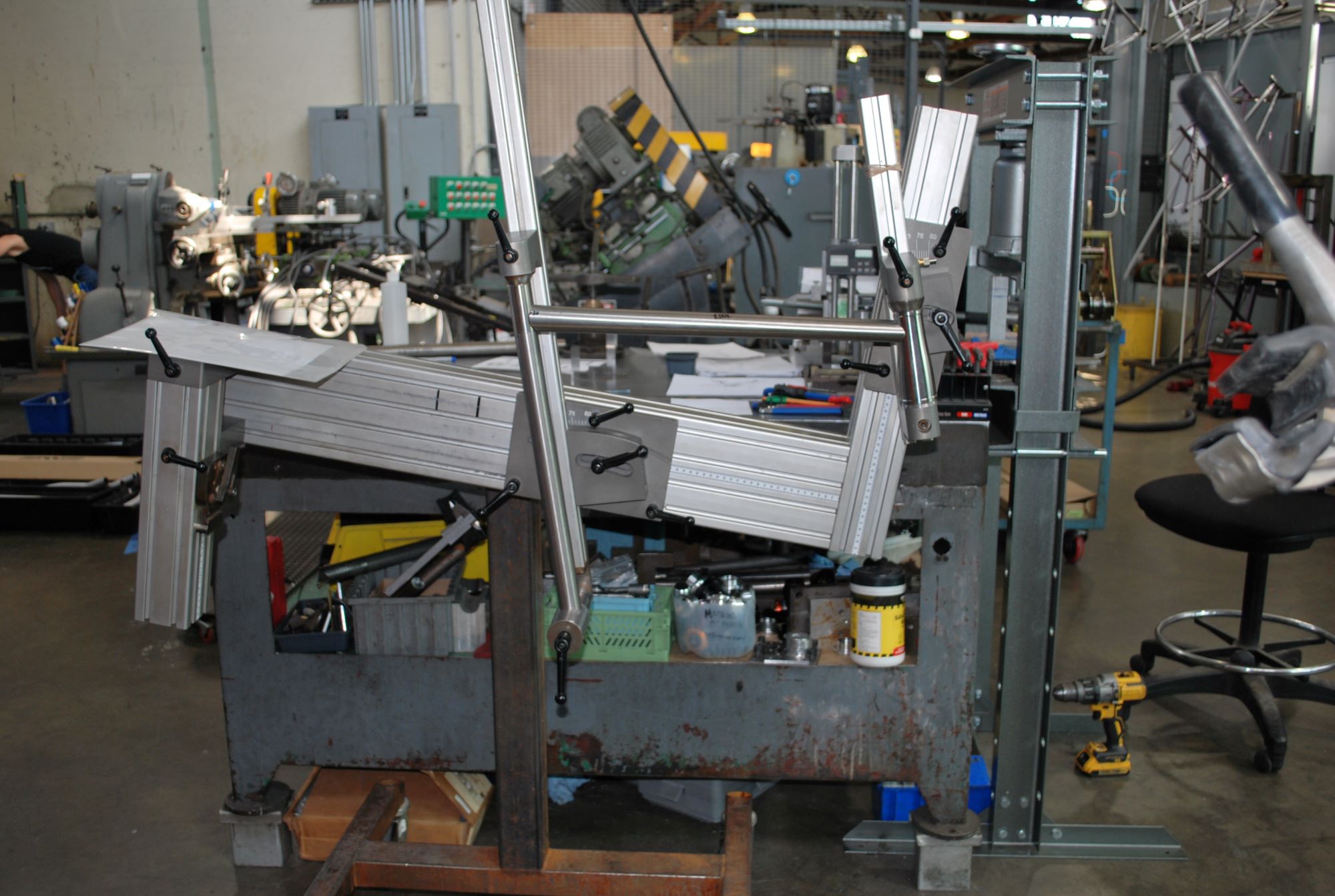

Another aspect to keeping costs down is via design, says Jordan Myers, the Director of Operations for Lynskey Titanium Bicycles. Lynskey is based in Chattanooga, Tennessee and is notable for the fact that it produces all of its bicycles in the U.S. with U.S.-made tubing. Lynskey offers bicycles made with both drawn and welded tubes, and according to Myers, welded tubing can be made stronger than drawn tubing, which makes it even more durable and well suited to riders who are hard on their equipment. It’s also cheaper. Durability is a focus point for Lynskey and the company has an excellent warranty policy to back this up.

Myers also highlighted several other ways that Lynskey is able to keep prices low, despite the costs of domestic manufacturing. The company’s titanium frames range in price from $1,200-$2,200, and are often on sale for even less.

He described how economies of scale work in Lynskey’s favor; a lot of bikes built at the same time on the same tooling equals less time per frame, and thus less expense. Simplifying the design also helps: avoiding things like internal routing and complex finishes keep costs down.

One interesting design feature Lynskey has developed is an indexable nut system for the rear dropouts that provides an easier way to keep frames in alignment. All metal bike frames undergo changes during the welding process as the heat and stresses subtly alter the tubes. One of the most time-intensive parts of the process is keeping the frame aligned after welding, but Lynskey’s design, which uses very slightly different size nuts to fine tune the rear wheel spacing eliminates the need for this step.

Where frames are made affects prices too. Brands like BlackHeart and Priority manufacture frames in China and Taiwan, while Lynskey, as discussed above, manufactures in the U.S.

Decathlon’s frames are made in Italy and the company says it has been proud to “develop a high-quality frame in partnership with Dedacciai in Italy, assemble it in France, and ship it globally—still at an excellent price point. The labor required to build a quality titanium bike is significant, and the tier-1 welders that make these bikes are few and far between.”

Additive manufacturing

New technology also allows titanium to be 3D printed, opening up an additional avenue for manufacturing small parts when the usual methods—typically milling or forming—aren’t feasible.

R+D engineer Johannes Thumm of Canyon Bicycles, which at the moment only makes carbon and aluminum bikes, revealed that the brand is playing with 3D printed titanium quite a bit.

“We’re continuing to investigate titanium manufacturing techniques which will be used in the production of future components, although at this stage it's too early to put a timeframe on that,” he said.

Canyon has been working with a company called IperionX to develop more sustainable manufacturing techniques.

“Before we started working with IperionX and their innovative process, extracting titanium was costly and complicated, requiring lots of energy and chemicals (using the Kroll process) and it couldn’t be properly recycled. This all changed with IperionX’s new HAMR-process, making titanium the perfect material in terms of performance and sustainability,” Thumm shared.

Like the companies above, Canyon was drawn to titanium for its unique characteristics. “It has excellent properties for building bikes and components. It is the metal with the highest strength-to-weight ratio, it’s corrosion-free, and it’s extremely durable. It can also be anodized in multiple colors, so it doesn’t need to be painted,” Thumm explained.

It will be interesting to see where Canyon goes with this, as the company is a major industry player with sponsorships at the very top levels of professional cycling. Canyon isn’t the only company doing this either: Colnago is another major brand making use of 3D printed parts on its C68 titanium road frame. The technique allows for small adjustments to stack and reach to customize fit, but is currently only available on one single model. It seems likely we will see more and more bike manufacturers explore ways they can utilize this manufacturing technique.

Are affordable ti bikes the future?

The rise of gravel riding and racing has changed the bike industry landscape significantly. Riding this wave of popularity are several companies that have realized that titanium offers characteristics that are well suited to gravel bikes. These affordable titanium brands offer impressive bikes at competitive price points and though they might have to work a little harder to fill a niche, most seem to be thriving. They’ve found ways to use titanium to make durable and high-quality bicycles but without the $6,000+ price tag of high end brands like Moots, Mosaic, Seven, Firefly, No22 and many more.

They do share a material, but fundamentally are different products for different customers

The final question we set out to answer was how these affordable bikes stack up against higher end titanium offerings. What we found was that it’s not really fair to compare the two. They do share a material, but fundamentally are different products for different customers. The reasons have to do with scale, audience, and customization.

Building bikes with custom geometry and finishes means much more time is spent on each individual bicycle, as it takes much longer to physically manufacture each piece one at a time. But there’s also the time spent communicating with customers to nail down the details like paint or anodization as well as each rider’s desired handling characteristics.

All of the more affordable brands mentioned above make stock sizes with little to no customization as part of their process. Without these complications in their process these brands are saving all of the time and associated costs and passing those on to consumers.

Mosaic and Moots both make stock sizes as well as custom, but also include features like more significant tube butting, tubing selected specifically for a rider or frame size, higher-quality finish options and custom features not related to geometry such as fender and rack mounts.

For people who do need or want custom geometry as well as details to make their bike unique to their needs, boutique brands can provide that service. It might cost more, but having a bike made just for you is something an off-the shelf bike simply cannot compete with. And anyone who might be attracted to titanium and is fine with stock geometry and doesn’t want the expense and complexity of a custom bicycle now has several more affordable options to choose from. What a time to be alive.

Tyler Boucher is a former (and occasionally still) bike racer across several disciplines. These days, he spends most of his time in the saddle piloting his children around in a cargo bike. His writing has appeared in magazines published in Europe, the UK and North America. He lives in Seattle, Washington.