The entrepreneurs from Wisconsin creating chromed carbon bicycle frames in a farm shack

The office has been constructed from “plastic sheeting, 200 light bulbs, 2 exhaust fans, and about 1,500 staples”

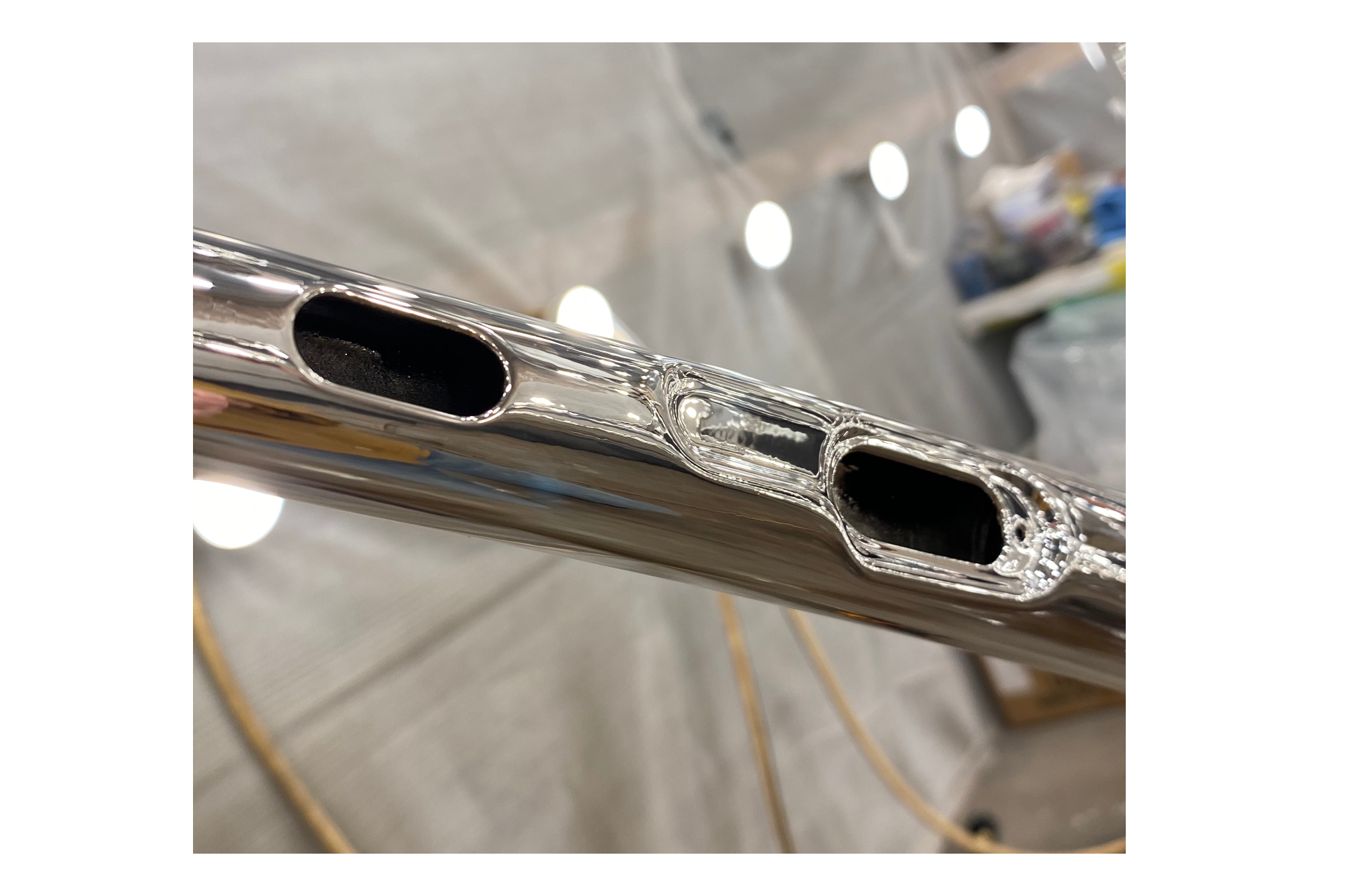

A pair of entrepreneurs say they have created the 'world's first chrome carbon bicycle frame'.

Here at Cycling Weekly we're not convinced this is a 'world first', but the duo's method of painting, and ability to create a 'production level' system where bikes can be painted at a relatively low expense, and quickly, is a new one on us.

Having seen pictures of the chromed bicycle on Facebook, we got in touch with one half of the production duo – and it turns out the pair have some major aspirations.

“The technology we’ve created will change the chroming industry – not just for bicycles. We can chrome anything. Hell, we chromed Gary’s shoes!” Tom Griffith tells us, referring to the footwear of his partner at 'Argent Brothers/Custom Industrial Coatings', Gary Elmer.

Griffith, a classic car enthusiast, and Elmer developed the tech in a "shack, in the middle of the woods, on a 400-acre farm", which they constructed from "plastic sheeting, 200 light bulbs, 2 exhaust fans and about 1,500 staples," Griffith told us.

The project was effectively a Covid-19 inspired hobby that went large scale, as Griffith explains: “To chrome plate something, the object has to be metal. Spray chrome technology can be applied to other surfaces and uses pure silver. But it's meant for small objects – tools, model cars. During Covid I had a lot of time on my hands... so I did some investigation.”

The pair, from Wisconsin, USA, say they've invested $90,000 of their own money and 2000 man hours into creating a chroming method that allows them to cover an entire carbon bicycle. The project has been nine months in the making, and they obtained frames from 'various sources'.

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

Is it really a world first?

The 'world's first chrome carbon bicycle frame' statement had us wondering, so we spoke to a few UK painters.

Dave Crowe at Colour Tech said: "I haven't seen a full chrome spray painted bike, in the UK... It may have been done on a classic car, in the US, but as individual parts. The complexities include getting round the bike, getting inside the chainstays, seatstays, without overspraying, there's loads of different angles and surfaces - I'd love to see it!"

Lee Prescott at Meteor Works, however, told us: "We have achieved a spray chrome painted frame, using hydrochrome tech, but that was labour intensive and couldn't be produced at a mass production scale. I don't think they're the first to do it but it is the productionisation that is the intellectual claim they have."

Explaining the complexities, Griffith told us: "Spray chroming technology has been out there for about 25 years but is meant for small parts and pieces, not something as complicated as a carbon bike frame with all its angles and holes, not to mention the size of the frame itself. We altered the traditional process in nine different ways to accomplish our goal.

"We have developed and designed a special 'chroming room' which allows a person, or small team of people, to do as many frames in a single session as they want to. The nine modifications that we have made to the traditional spray chrome technology were implemented to specifically address the 'production process' and the ability to chrome a continuous line of frames in a single chroming session without interruption. Our system takes full advantage of the economies of scale and limits the amount of waste," he says - stating that a single frame chrome spray using this method takes 15 minutes.

"Many of the bike companies have been trying to do this for years, and subsequently failed," Griffith asserts.

Is it heavy? Resilient? Expensive?

So, what's the price for a shiny frame, in grams? Does it last, and is it expensive? The answers we got were reassuring, though we can't pass judgment until we've seen a frame in the flesh.

"We're using 0.999 silver, which measures just 4/10,000ths of an inch thick", Griffith tells me.

Each frame needs to be clear coated, before the silver is applied, then clear coated once again – but he says "the paint on most bicycles is 20 times thicker than the silver we're using, so in every case, the bike we've chromed has been lighter than if it would be painted in the traditional way.

"We knew to make this viable we needed to be able to mass-produce, and we can apply this method to a frame for under $100," Griffith tells us. Each frame uses around 2 ounces of silver, but Griffith says only about "a tenth of that actually sticks to the frame, the rest is rinsed off."

Griffith says the result is weatherproof, scratch-resistant, and because the silver is flexible, it can flex and take a beating without being damaged. "If you dropped it you might scratch the clear-coat, but that would be the same with a traditional frame, too," he says.

Spray chroming is nothing new. First, a base coat is applied. Then comes a pre-activator – which is washed off with distilled water – then an activator – also washed off with distilled water. Then comes chrome via a dual-head spray gun, before more distilled water and an antioxidant treatment and a blast of air. The process doesn't require the chemicals used in traditional metal chroming, which Griffith describes as "horrific". But this is usually all done on a small scale.

Detailing the difficulties in production when it comes to bikes, Griffith explained: “The main reason it was considered impossible to spray chrome a bicycle frame is because it’s large and it has a lot of holes... if you cover the holes with tape or even fill them with rubber plugs, the chrome solution – silver nitrate – gets behind the coverings. If even one single drop gets into the frame and comes out of one of the holes, it shadows the chrome and ruins it.

"We came up with a production process to completely eliminate that factor. We don't plug the holes at all now, we don't have to.”

Then, there’s the size of the bike. “All spray chroming companies start from the bottom and work their way up – whatever item you're spraying. Because a bike frame is so large, by the time you get to the middle of the frame, all of the material below is sticking and all the carbon above you haven't got to yet – by the time you get to it, things are running down because of all the water you're using, it causes drips and it's not consistent. So we had to think of a way to eliminate that factor. Making the whole bike like a perfect mirror.

“Finally, the coating of the frame is so thin, it mirrors anything it goes on, so even a speck of dust on the frame will ruin it. Remember we're doing this in a barn. On a farm! If one tiny piece of dust hits that frame, you can't take a microfibre towel to the frame and wipe it off because those micro scratches from the towel will show through the chrome. So we had to overcome that too.”

What’s next for this pair? And when can you buy a chromed frame? Well – first someone out there is going to have to buy the tech from Elmer and Griffith.

“We’re at the point that we’ve spent all this money – and we’re broke! The suppliers of some of the components that we use have pleaded with us to tell them how we did this, but to date, we have declined. We believe the best purchaser of this new 'production level' system should be sold to a bicycle manufacturer or an international racing team. We want to sell what we know. We have designed a room, for them to build, so they can do this in house.”

Interested parties can get in touch with the pair at argentchrome.com/contact.

Michelle Arthurs-Brennan the Editor of Cycling Weekly website. An NCTJ qualified traditional journalist by trade, Michelle began her career working for local newspapers. She's worked within the cycling industry since 2012, and joined the Cycling Weekly team in 2017, having previously been Editor at Total Women's Cycling. Prior to welcoming her first daughter in 2022, Michelle raced on the road, track, and in time trials, and still rides as much as she can - albeit a fair proportion indoors, for now.

Michelle is on maternity leave from April 2025 until spring 2026.