Valentino Campagnolo: The Big Interview

Just as the US had its historic Big Three car manufacturers, cycling has its Big Three: SRAM, Shimano and Campagnolo. They all produce top-quality parts for bicycles, but Campagnolo has the edge.

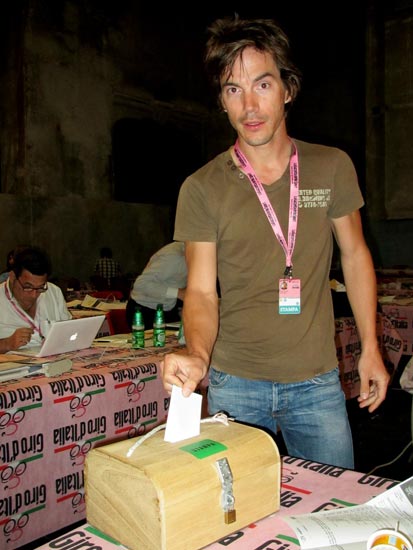

After inventing the quick-release mechanism 80 years ago, it has remained at the forefront of bike technology ever since. It takes expertise to remain at the top. President Valentino Campagnolo explains his father's approach and why his company's future is electronic.

CW: Were you more intrigued by the cyclists your dad Tullio helped or the equipment he made?

VC: When I was young, I did not have a clear idea about our product, so the cyclists drew me in. But from that was born with a link to the world of cycling.

Did you go with your dad to the races?

VC: Yes. From that, I was able to understand what cyclists had to go through for their work. If you just watch on your TV, you do not see that. You do not see the riders racing down the descents at 80kph, weaving between the team cars, where there are no guardrails. They have a special saint watching them I think.

He was an inventor, but you studied economics...

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

VC: He had the ability to imagine and plan products. I do not have that ability, I would like to, but I do not.

But you have the talented workers to design products?

VC: R&D is our tried and true method of developing. The ideas can come from anyone though, a client, a store or an article from a cycling magazine. Some of the ideas may be developed immediately, but some of them may take years before they are developed because the means does not yet exist. We also have to decide which ideas will give the most impact for our company.

Do you have an example of a product that took years to develop?

VC: [Laughs] This is a good way to arrive at the main topic, the electronic components. It has been particularly difficult. The company did not have the competence in that field; our company had its strength in metal engineering. However, we are a company that knows how to overcome challenges. Some companies can't do that even if they wanted to.

Like using carbon-fibre?

VC: We found ourselves in trouble so we asked the experts in the field. We found someone to help us and today, we have four different ways of working with carbon-fibre, such as unidirectional and monocoque forms.

Tullio Campagnolo

Did you have to learn it all from scratch?

VC: It was difficult and costly, but very important. However, once you are able to work with carbon-fibre you have the possibility to come up with other developments. It was the same way in the electronics field; we did not know anything, apart from the operators who were pushing the machine buttons.

Would it be better to develop a 12-speed group versus an electronic group?

VC: I can confirm we are not working on a 12-speed group. I do not know if it would be easier, but I can tell you the step from 10 to 11-speed was a lot more difficult than we initially imagined. We knew we would have to miniaturise everything, but we did not know that we would be practically building a wristwatch.

Did Shimano's electric group force Campagnolo to develop its own?

VC: No, because Campagnolo started before Shimano. We started a little after Mavic did [in 1994]. Certainly, Japan has a history in the electronics field and this gave our rival a competitive advantage - a huge advantage. We could have anticipated our rival [Shimano] if we would have reversed our priorities. Instead, we gave priority to an 11-speed group [released in 2008].

Are electronic groups the future of cycling or do they overcomplicate the bicycle?

VC: It will evolve the components group and the bicycle as a whole. However, it's a complex product when you compare it to the mechanical group. Our goal is not to make it less complex, that's impossible, but to make it simple to use. We don't want to require users to be electrical engineers.

How did Shimano's arrival in the 1970s force Campagnolo to improve or think differently?

VC: Any rival's contribution forces and encourages us to do more. We don't only watch them, though, we listen to what our clients are saying.

What impresses you about Shimano?

VC: The technical research that Shimano gives to its products. Their parts are not just good, but extraordinary. They succeeded in working hand in hand with the mountain bike movement in California. They were able to able to nurture that big market. That was a huge victory.

And SRAM?

VC: SRAM has a very good marketing approach. The Americans are always good at marketing. They offer a good mix of components that are optimal for the market - technical and economic. Every company has to have its own personality and approach. Campagnolo still has the same approach as 50 years ago, one that is different from our rivals. If they were similar to us then they would fail, others have tried and failed.

Were you afraid Campagnolo might lose one of its top assets, that it is Italian, when it decided to export some production to Romania in 2006?

VC: No, because everything that goes into the production of those products happens here in Vicenza. We develop the stamps and the quality control methods here and take them to Romania, where our Italians explain how to produce the part.

What do they do there?

VC: Two things: work with carbon-fibre and assemble all of our components. The carbon parts that are made there are only the ones where we have already established a stable quality level; otherwise, we produce it in Vicenza.

Is this the modern reality of any Italian company?

VC: Yes. The work done in Romania is manual labour that would be costly here. Making a carbon-fibre part requires less craftsmanship, but a lot of manual labour. And since the products are continually evolving, it is impossible to programme robots here to do the work.

Does Campagnolo lose its ability to say it is ‘Made in Italy'?

VC: What is done in Romania is first developed and fine-tuned here in Vicenza. So, all the

know-how remains in Italy and it is secretive.

Why Romania and not China?

VC: Because Romania is not far from Italy, it is in the EU, its people speak a language similar to Italian... I think it has been

a good decision.

What makes a part a Campagnolo part?

VC: We try to put the Italian flavour into every one of our products, our way of being. It is similar to what Ferrari and Lamborghini do and what you can't find in other countries. They are clearly different from BMW.

As Campagnolo is different from Shimano?

VC: If you compare our products with the others, you can clearly recognise them. It is not just because of the name. The difference is the detail, the development of solutions that may seem costly and not necessary, but produce lightweight and durable pieces. We do not subscribe to throwaway products, we want them to last and be maintainable. This is not just the case with Super Record, but all the way down to the Veloce range.

Do you not think that your rivals have the same approach?

VC: I do not think so. I think they have a different approach. If you look at their products, I think you can get an idea of what is behind them, the company's intent when they developed them. If anyone takes the Ergopower lever of Super Record, Chorus, Centaur...

I think they can see that the same person oversaw the development and that he used the same criteria in their development.

This article originally appeared in Cycling Weekly magazine, December 2 2010 issue

Gregor Brown is an experienced cycling journalist, based in Florence, Italy. He has covered races all over the world for over a decade - following the Giro, Tour de France, and every major race since 2006. His love of cycling began with freestyle and BMX, before the 1998 Tour de France led him to a deep appreciation of the road racing season.