There’s so much ugliness in cycling, I fear for its future

My New Year’s wish is for a more intelligent response to progressive bike tech in 2025

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

You are now subscribed

Your newsletter sign-up was successful

In recent weeks, four notable product launches left me choking on my breakfast porridge: two from Colnago, one from Wahoo, and one from Jaguar.

The first, the Colnago Steelnova, is an achingly beautiful bike hand-fashioned from Columbus steel tubing with a trolley load of Campagnolo components lovingly bolted on. It carries the graceful air of a ‘restomod’ - a craftsman-honed modern classic, built to traditional proportions using time-favoured materials but with just enough modern tech – 3D printing and an electronic groupset – to bring it into the 21st Century without upsetting the purists.

Its appearance garnered such outpourings of adoration and adulation that Colnago sold all 70 of these £16,000 limited edition bikes in just two hours. That, right there, is the monetary power of nostalgia - £1,120,000 at £9,333 a minute.

The Colnago Steelnovo was a sell-out success

As for the other launches – vain attempts to flog progressive products to a deeply conservative market – what were they thinking?

Colnago’s second launch was the Y1Rs, a state-of-the-art aero bike that will be Tadej Pogačar’s ride for the flat bits of the forthcoming WorldTour. Colnago says that, with its innovative seat tube seatpost junction - made possible by changes in UCI rules dictating design - and gullwing bars, it's the “most aero road bike in the WorldTour” and “faster than the fastest competitor”.

The overwhelming consensus online? “It’s ugly.”

Colnago's departure from the traditional double diamond prompted harsh reactions

Wahoo’s new Elemnt Ace is the brand’s most powerful bike computer ever. It has a wind sensor, much-improved battery life and a larger, more legible display with millions of additional colours.

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

The overwhelming consensus online? “It’s too big.”

Of course, cycling is not the only industry where kneejerk monosyllabic judgements hold sway. Jaguar’s brave ‘Exuberant Modernism’ brand reboot (we rarely feature car manufacturers in Cycling Weekly, but Jag is currently not manufacturing anything other than disdain, so hey ho) was universally condemned too. It’s trying to reposition itself from a heritage brand to, well, a relevant brand. But all Jag diehards want is the backwards-looking E-Type back. Until they get that, they’re going to kick up merry hell, blind to the fact that their viewpoint is a window to a successful past rather than a successful future.

Jaguar's ‘Exuberant Modernism’ reboot (bottom) was brave, but, fans just want their old 1963 E-Type (top)

Jag is relevant here because almost every well-known cycling name is also a heritage brand with at least 50 years’ worth of both palmarès and baggage - Colnago, Pinarello, Wilier, Bianchi, Raleigh, Scott, Cannondale, Specialized, Cinelli, Giant, the list goes on. Even Trek is 48 years old. Worse still, our industry, pastime, sport – call it what you will – is dominated online by retrogrouch traditionalists who, just like those blinkered E-type fans, refuse to let these brands breathe fresh air into what is fast-becoming a stale industry.

It’s not the products that had me spluttering into my cereal bowl, it’s the thoughtlessly negative judgements from the super-opinionated

This, for me, is where the ugliness in cycling is. It’s not the products that had me spluttering into my cereal bowl, it’s the thoughtlessly negative judgements from the super-opinionated, usually on social media but increasingly within the mainstream media too.

This broad-brush cynicism about anything new or progressive is stifling innovation in cycling. For goodness sake, we’re still wasting time debating the merits of disc brakes, tubeless setups, e-bikes and whether gravel’s a ‘thing’. Who can blame the aforementioned brands for playing safe with product launches? It’s easier and less confrontational to keep doing the same old thing, with a few tweaks here and there.

A showcase to the next generation

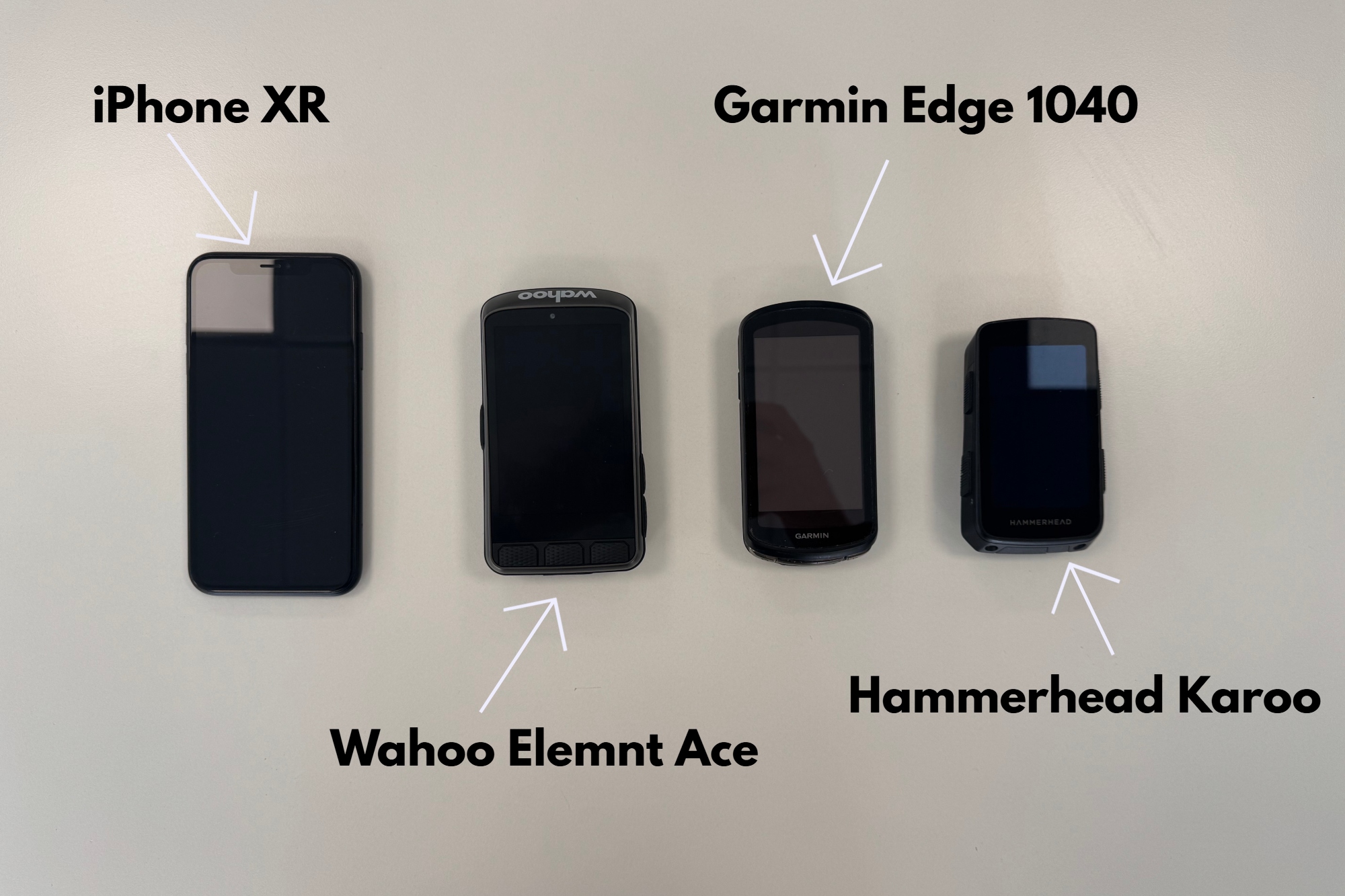

For better or worse, Colnago and Wahoo have been more courageous. I haven’t used the Elemnt Ace (tech writer, Joe Baker, has been hands on - read more here) yet but I was given a prototype to play with at Eurobike. The headlines, memes and parodies on social media would have you believe it’s like strapping an iPad to your bars. Or, at the very least, an iPhone. Well, I hate to disappoint but it’s really not that big. I own an ageing regular iPhone 11 and it dwarfs the Ace. It also has a fraction of the battery life. So, I’d ride with an Ace or Edge 1050 on my bars in preference to my phone all day long (doubly so, because my phone won’t do ‘all day long’). If, like me, you’re an endurance rider who requires nav frequently, these two larger head units perform so much better than their smaller counterparts.

The Wahoo Elemnt Ace is larger than other computers, but still smaller than an iPhone XR

I’m also yet to ride the Y1Rs but I have spoken at length with its designer Davide Fumagalli, Head of R&D at Colnago, an opportunity that, no doubt, will have passed the keyboard warriors by. Two things in particular excite Fumagalli about the bike. Firstly, wind tunnel testing was more stringent than anything that Colnago, or any other brand as far as Fumagalli knows, has ever done before. It invested two years in the process. Secondly, the Y1Rs project gave Fumagalli and his team the opportunity to develop something fresh.

“We want the new generations to look at a bike and see something futuristic,” Fumagalli told me. “Something with which we are opening their hearts as a design thing, and not a bike thing. We need to provide them with something cool, not a traditional bike with a double triangle. We need to showcase to the next generation that we are moving forward with a faster and better product."

Of course, beauty is in the eye of the beholder, but the Y1Rs deserves more than to be simply dismissed as “ugly”.

Bike design is falling behind

The ironic thing is that the majority of these heritage brands were once progressive innovators. It’s this quality that made them so special in the eyes of the public, who unfortunately reciprocated by demanding they be preserved - treasured, if you like - in aspic. Campagnolo springs to mind - damned if they try to reinvent themselves, damned if they don’t.

Sitting on one's laurels as they slowly compost is not a sustainable approach for any brand. Heritage marques may retain appeal and respect from some older, less transactionally active consumers, but younger generations are likely to reject them as irrelevant. They demand better of us.

It’s shocking that the bicycles we ride in 2024 are recognisably similar to those being ridden in 1924. Every other form of transport bar walking has moved on, after all, most of us happily consider steam trains, biplanes and Model Ts as museum pieces.

Other areas of transport have been allowed to move on, why not cycling?

It’s also alarming that bike brands are going to the wall almost monthly, the British racing scene cannot put forward a single men’s Continental team for 2025, and loss-making British Cycling’s membership has fallen by 11 percent over the past 20 months. Cycling in the UK is not moving forward, and in the US interest in the road racing scene has dwindled, hardly surprising since the country’s last Tour de France win dates back to 1990. The gravel scene, comparatively, has exploded - because it brings with it a newness that road racing’s stale exterior does not promise. While exciting products won’t fix all of this, they will broaden the appeal to a wider audience and help to grow the discipline, from grassroots to elite sport.

Progressive technology isn’t necessary, but it opens doors to new possibilities

Cyclists are often suspicious of brands for marketing products to us that we don’t need. There is an element of truth in this. Nobody needs a large GPS computer screen, the same way we didn’t need navigation - but many of us would now be lost without it. Nobody needs bike design that goes beyond the traditional double diamond, the same way we didn’t have to relegate steam trains, but the world moves faster when we let it move forward.

Progressive technology isn’t necessary, but it opens doors to new possibilities. The reality is that it’s much easier and cheaper for brands to give us what we want. If that want is the same old, same old then we’re going to get what we deserve. The same old, same old.

My hope for 2025 is that we’ll be more open to innovative change, leaving the brands more open to design products that aren’t constrained by the confines of bigotry and tradition.

Simon spent his childhood living just a stone’s throw from the foot of Box Hill, so it’s no surprise he acquired a passion for cycling from an early age. He’s still drawn to hilly places, having cycled, climbed or skied his way across the Alps, Pyrenees, Andes, Atlas Mountains and the Watkins range in the Arctic.

Simon now writes for Cycling Weekly as a freelancer, having previously served as Tech Editor. He’s also an advanced (RYT 500) yoga teacher, which further fuels his fascination for the relationship between performance and recovery.

He lives with Jo, his yoga teacher wife, in the heart of the Cotswolds, with two rescue cats, five bikes and way too many yoga mats. He still believes he could have been a contender if only chocolate weren’t so moreish.

You must confirm your public display name before commenting

Please logout and then login again, you will then be prompted to enter your display name.