What is a tubeless tire? Everything you need to know about tubeless tech for road and gravel bikes

Thinking about 'going tubeless'? Here's a short guide to the tire and rim technology

In recent years the best tubeless tires have grown in both prominence and popularity. Once the preserve of mountain bikes, they are now widely used on both gravel bikes and the best road bikes.

But what is a tubeless tire exactly, what are the pros and cons of 'going tubeless', and are tubeless tire setups easy enough for everyone to use?

As the name suggests it’s a tire that’s fitted without an inner tube. It’s how modern car tires roll, and the principle remains the same for bikes, too.

Continue reading to find out more about the benefits, the drawbacks, what to do when a tubeless tire is punctured, and more.

How do tubeless tires work?

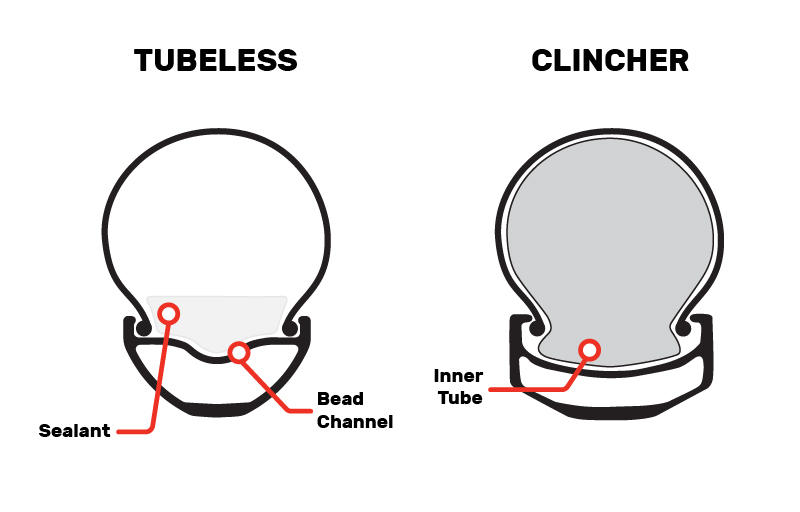

A tubeless tire can forego an inner tube by creating an airtight seal between the bead and the rim. A valve is still required, with a tubeless-specific valve inserted into the valve hole and made ‘air tight’ via a nut or collar. Specific rim tape is also needed if your rims have drilled holes in the rim bed (created to allow the nipple to attach to the spoke more easily).

As you’d imagine creating a truly airtight seal is paramount to the effectiveness of any tubeless set-up. Specific bike pumps are available - often referred to as ‘inflators' - which help fill the high-volume tires typically used in tubeless set-ups quickly and efficiently. However, as both tire and rim technology has improved many of the best tubeless tires can be successfully seated with a regular track or floor pump - you can find our recommendations in our guide to the best bike pumps.

A dedicated tubeless sealant is also added to the inside of the tire and is designed to plug small leaks caused by a puncture as well as helping the system to become airtight. The sealant can be poured directly into the tire before its seated or injected through the valve - the latter method tends to be both cleaner and less wasteful. Find our guide to the best tubeless sealant over here.

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

What are the benefits of a tubeless tire?

There’s a reason that mountain bikers were quick to embrace tubeless technology. The main advantage of the system is that it allows users to run their tires at significantly lower pressures, which aids grip and improves comfort. On unforgiving trails both elements are greatly appreciated.

And why can you get away with these lower pressures? Because no inner tube means no risk of a pinch flat. This occurs when a tire squashes the inner tube against the rim and typically happens when the tire takes a big hit, something that’s commonplace when riding gravel for example. The lower the tire pressure the more the tire is likely to deform, which in turn increases the chance of a pinch flat.

Many advocates of tubeless technology also believe them to be faster, offering less rolling resistance than a tubed equivalent. Much testing has been done in this realm and certainly it makes sense with regards to less than perfect riding surfaces, where lower pressures help to reduce ‘vibration loss’.

Zipp, who manufacture tubeless rims and have played a considerable role in measuring the impact of vibration loss, describe it as “the force opposing forward motion encountered when lifting the rider-bicycle system over small bumps many times per second”. In essence it means that on rougher surfaces both bike and rider are forced upwards, which halts forward momentum.

As Zipp explains: “Whole-body vibration while cycling stems from the inability of a tire to fully deform around bumps. Higher tire pressure leads to more vertical movement of the bicycle and rider. Lower tire pressure helps maintain a constant elevation of the center of gravity by cutting out road input. The real-world examples above show that absorbed power can account for significant losses of efficiency."

This reasoning has played a role in the growth of tubeless tires on road bikes, dispelling long-held beliefs that narrow tires run at higher pressures are faster on the road. Given that most of us spend at least some of the time riding on road surfaces that are far from ideal, wider tires run at lower pressure starts to make a lot of sense. And it could well be argued that tubeless technology is likely to enhance the effectiveness of this combination.

What are the drawbacks of a tubeless tire?

If you’re used to fitting inner tubes then the tubeless process may seem a little daunting at first. It can be more time consuming, and a little messier too given the use of sealant. However, we’d suggest that like many aspects of bike maintenance, the more you do it, the easier it becomes.

That said, you will need to keep topping your tires up with sealant. How often depends on the brand, with some drying out faster than others. As a rough guide expect to have add sealant every two to four months.

Tubeless set-ups rely on being airtight, and with the tires, rims, valve and rim tape all capable of springing leaks, it can be a frustrating game. You’ll also need to regularly inflate your tires as even when installed correctly there will be some pressure loss.

Do you need specific tires and rims to go tubeless?

Given that you need to create an airtight seal between tire bead and rim, using tubeless specific tires and wheels is wholly encouraged, even if it’s for safety reasons alone.

A tubeless tire benefits from specially designed beads and casings. The beads are created to resist stretch helping to avoid blowouts, while the casing is usually sealed.

Likewise tubeless wheels are designed for the job. Typically they’ll employ a central channel, which aids tire fitting. Some wheels will use bead hooks to help keep the tire in place while others will feature hookless rims that need to be used with compatible tires - non compatible tires could roll off the rim.

Why hookless? Two of cycling's favourite obsessions - weight and aerodynamics - play a part, with makers of hookless rims claiming them to be lighter while allowing for a shape that creates less drag due to the way the tire and rim interact. There’s also an argument that hookless rims allow for a stronger wheel too. Significantly, they’re cheaper to make, which should, theoretically at least, mean more affordable wheels for consumers.

As mentioned compatibility with hookless rims does currently limit the range of tires that you can use with this technology.

It's probably worth pointing out that even if you are using tubeless tires and wheels you can still fit inner tubes if you so wish.

Are tubeless, tubeless-ready and tubeless-compatible the same?

If you've been considering a move to tubeless it's likely you'll have come across both these terms on various wheels and tires. Indeed, you may already own a bike that has tubeless-ready or tubeless compatible components.

So what's the difference?

A true tubeless rim is one that doesn't have any drilled holes in the rim bed and therefore doesn't need the addition of any rim tape to help make it airtight.

A tubeless-ready rim is one with drilled holes and is far more commonplace. Its readiness is due to the bead lock design of the rim that helps to create a seal when the tubeless tire is seated, but it needs tubeless rim tape to seal those holes and a tubeless valve.

A tubeless-compatible rim is the same as tubeless-ready and will again need the addition of rim tape and valve to make it work.

As for tubeless-ready and tubeless compatible tires, again the terms are interchangeable and mean that the tire is compatible with tubeless-ready wheels. However, if you're using hookless rims you'll need to match these not only with a tubeless-ready tire but one that's compatible with the hookless technology.

What happens when a tubeless tire is punctured?

Nobody enjoys getting punctures and going tubeless should result in less of these unwanted pitstops.

We've already discussed the impact that lower tire pressures have on pinch flats, while the sealant should be adept at plugging any small holes in the tire you get while riding.

However, some holes will prove too much for even the best sealant. If this is the case, you'll need to insert a plug using one of the best tubeless tire puncture repair tools.

Failing that you could always fit a inner tube to get you home.

Luke Friend has worked as a writer, editor and copywriter for over twenty five years. Across books, magazines and websites, he's covered a broad range of topics for a range of clients including Major League Baseball, Golf Digest, the National Trust and the NHS. He has an MA in Professional Writing from Falmouth University and is a qualified bicycle mechanic. He has been a cycling enthusiast from an early age, partly due to watching the Tour de France on TV. He's a keen follower of bike racing to this day as well as a regular road and gravel rider.